Trilogy

r

Air Spray/LVLP Automatic Spray Guns

11

Part 1601058

−

03

E

2014 Nordson Corporation

Troubleshooting

WARNING:

Allow only qualified personnel to perform the following tasks.

Follow the safety instructions in this document and all other related

documentation.

These troubleshooting procedures cover only the most common problems.

If you cannot solve a problem with the information given here, contact your

local Nordson representative for help. See Figure 5 for parts information.

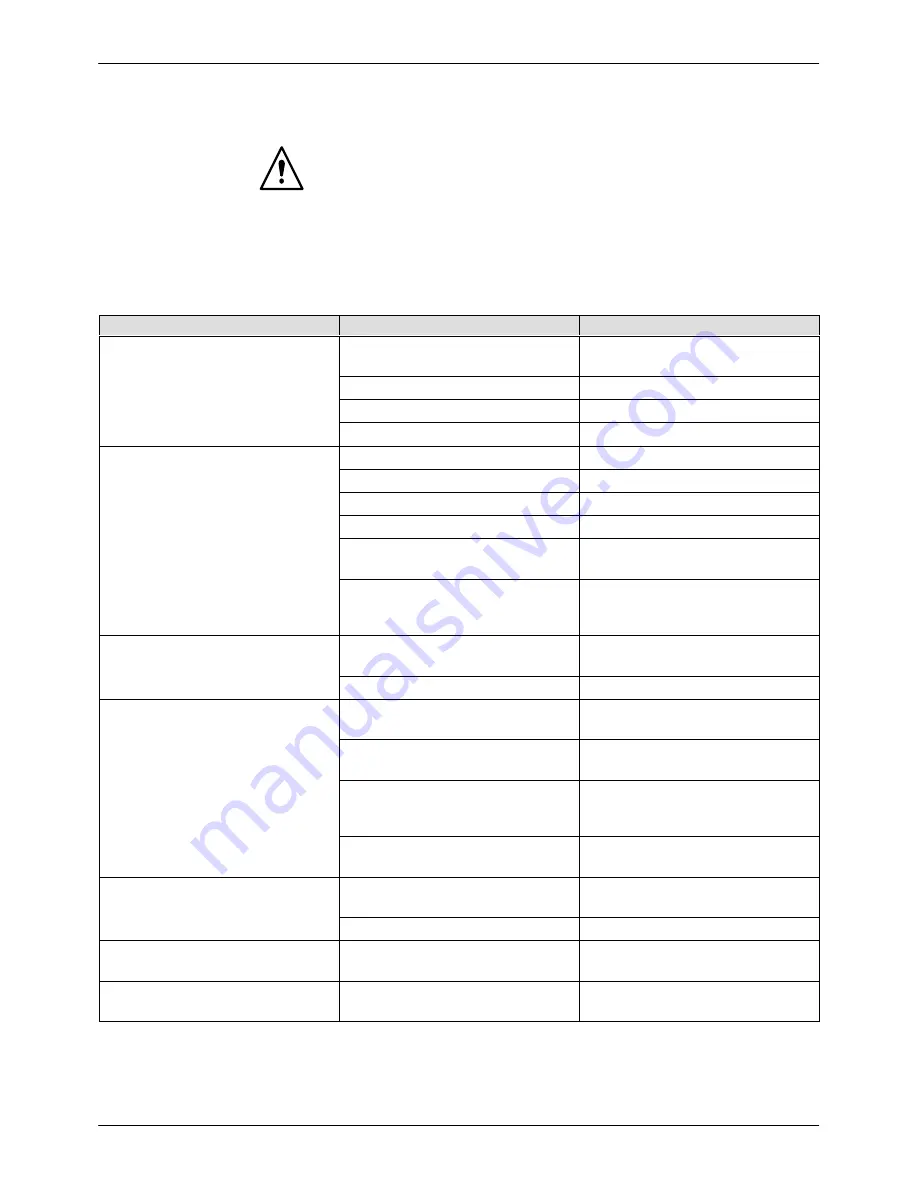

Problem

Possible Cause

Corrective Action

1. Paint flow decreases when

spraying

Fluid filter clogged

Clean the filter.

Viscosity too high

Lower the material viscosity.

Nozzle too big or worn out

Replace the nozzle.

Fluid pressure too low

Increase fluid pressure.

2. Irregular fan pattern

Nozzle orifice clogged

Clean or replace nozzle.

Fluid filter clogged

Clean the filter.

Nozzle too big or worn out

Replace the nozzle.

Viscosity too high

Lower the material viscosity.

Either not enough or no

atomizing air

Adjust atomizing air flow

(regulator R).

Air cap orifices clogged

Use a soft bristle brush and

solvent or waterborne cleaning

solution to clean the air cap.

3. Nozzle clogs

Material pigment too coarse for

nozzle size

Use a larger nozzle.

Fluid filter mesh too big

Use a smaller filter mesh.

4. Spraying continues when

gun triggered off

Nozzle or needle worn out

Replace the nozzle or needle.

Needle packing gland too tight;

needle cannot move

Loosen the needle packing gland

or replace the seals.

Piston springs worn out

Replace springs. Make sure

piston moves smoothly in

cylinder.

Solenoid valve triggering gun is

malfunctioning

Check solenoid valve operation.

5. Spray gun leaking fluid

from packing gland

Packing gland too loose

Tighten packing gland.

Needle seals worn.

Replace seals.

6. Air leaking from air cap

when gun not spraying

Piston seals worn

Replace piston.

7. Spray gun leaks air at

spring cap

Piston seals worn

Replace piston.