Trilogy

r

Air Spray/LVLP Automatic Spray Guns

9

Part 1601058

−

03

E

2014 Nordson Corporation

LVLP Compliance Kit Installation and Use

CAUTION:

If your location is subject to VOC emission regulations, make

sure your spray gun atomizing pressure is 0.69 bar (10 psi) or less by

testing with a compliance air cap. Refer to the chart on the following page

for maximum air inlet settings to achieve the 10 psi or less LVLP rating.

NOTE:

The gauge kit and the compliance air caps are sold separately.

Order one gauge kit and compliance air caps of the same size as the

production caps you normally use.

1. Shut off the fluid delivery system and relieve fluid pressure. This is not

required, but it will prevent fluid from spraying while performing the

compliance test.

2. Remove the retainer and production air cap from the gun. Install the

compliance air cap on the gun and tighten the retainer securely. (The

compliance air cap comes with its own retainer.)

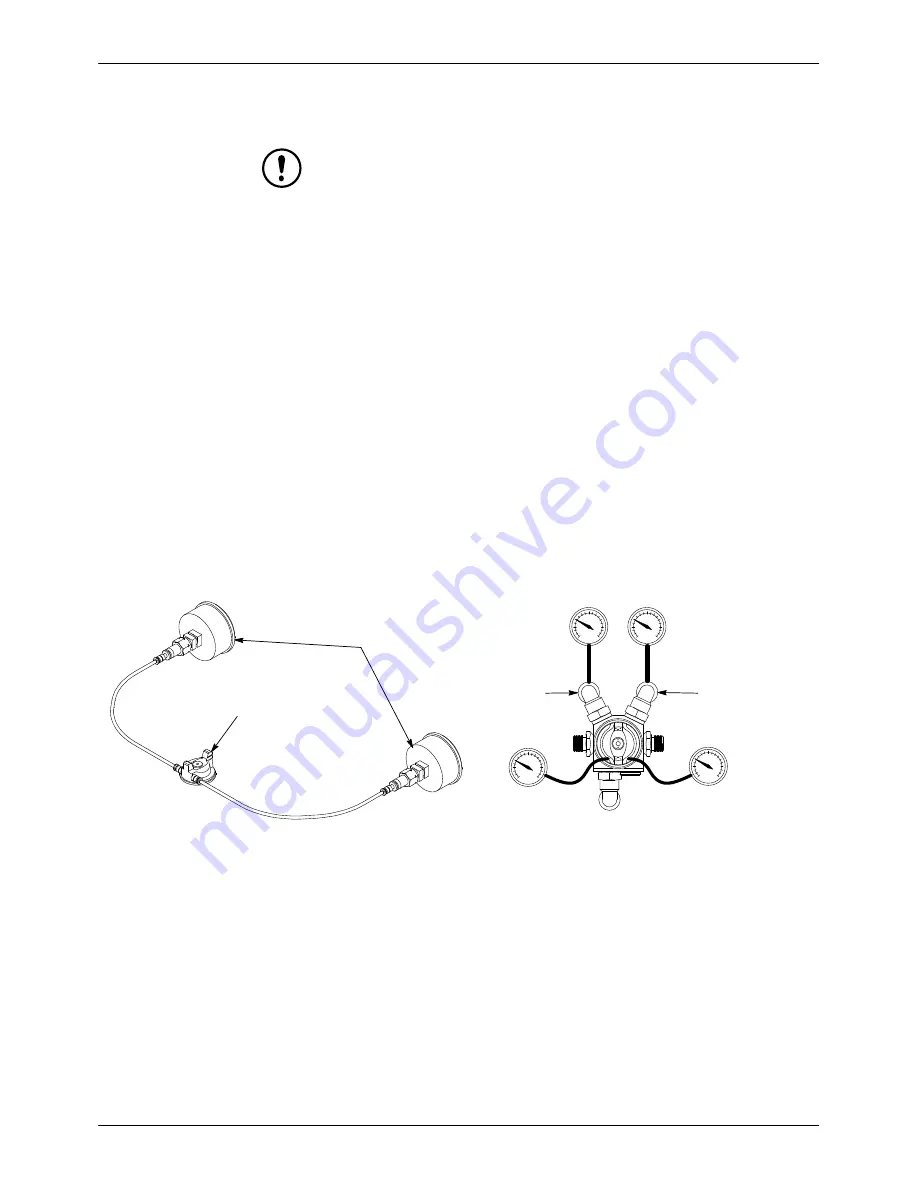

3. Connect the gauges to the air cap.

4. Fully activate the trigger air to allow full flow of horn and atomizing air.

5. Check the air pressure gauges. Both atomizing and horn pressures must

be 0.69 bar (10 psi) or less. If either is higher, reduce the pressure.

6. Reinstall the production air cap and check the fluid atomization. You

can check the atomization with the compliance air cap installed, just

make sure the gauge tubing does not impinge the spray or kink.

Air Cap

Gauge Kit

Horn (F)

Atomizing (R)

5 Ft. Tubing

0.69 bar

(10 psi)

0.69 bar

(10 psi)

Figure 4

Compliance Air Cap and Gauge Kit Installation and Use