108

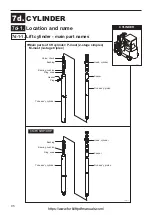

CYLINDER

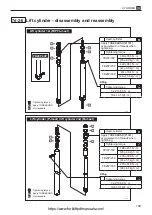

7d

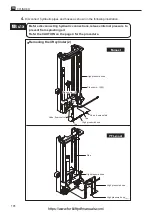

Preparation for disassembling

4

1

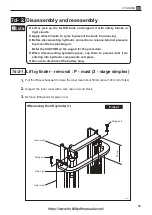

Make the preparations shown below before disassembling the cylinder.

l

Preparation of the workbench

The workbench should be wide enough to put the parts on. It should be stable and solid

so that the parts will not fall off or move during the maintenance.

l

Preparation of tools and materials

Prepare proper tools and materials.

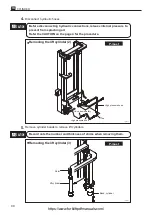

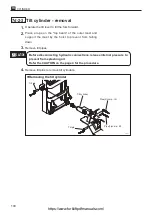

Maintenance standards

4

3

Replace the sliding parts and sealing parts according to the following instructions.

l

Bushings : When more than 1/4 of circumference is worn out and shows a red copper

color.

l

Seals : Whenever the cylinder is disassembled, replace them with new ones.

l

Piston rod : If curved more than 0.5 mm / 1m.

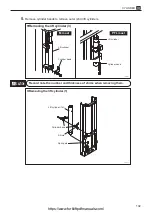

General precautions for the maintenance

4

2

l

Before disassembling the cylinder, thoroughly clean any dirt or dust on the outer tube.

l

Since these are precision parts, handle them with care. Handle the parts carefully so as

not to hit them against each other or allow them to fall.

l

Don't tap or pry any parts by force. Such handling may cause burrs or damage parts.

As the result, parts may be impossible to reassemble properly and causes oil leaking or

degrades the performance.

l

If the parts are left halfway while maintenance, they may be rusted or damaged by dusts.

They must be covered or protected if the job is required to interrupt.

https://www.forkliftpdfmanuals.com/

Содержание FB10P

Страница 2: ...https www forkliftpdfmanuals com...