XR67

3

If the alarm output and/or LED indicate a fault (RED) on a properly

mounted XR67 and the rotor is properly located, replace the XR67.

An oscilloscope can also be used to verify proper output of the

SMARTSafe™ encoder at the encoder connector itself and at the

drive/controller cabinet. If the outputs show large variations in the

signals at steady speed (jitter or “accordion effect”, see figure below),

check rotor position. If the rotor position is correct, the motor or

shaft may be highly magnetized. Replace any magnetized material

nearby with non-magnetic material (aluminum, stainless) (especially

shafts). For GE CD frame motors and similar styles, Avtron offers

non-magnetic stub shafts. If variations persist, consider replacing

the encoder with super-shielded models, option -005, or use retrofit

shielding kits AVSKxxx yy z, where xxx=model (ex: 67A), yy=rotor (ex:

CB), and z=cover (ex: F).

NOTE:

Do not use rotors from THIN-LINE I (M56, M56S, M67,

M85, M115) with XR67 This will cause incorrect PPR

output, but the XR67 LED will remain green.

ENCODER REMOVAL

The XR67 stator housing can be removed by loosening and removing

the socket head cap screws.

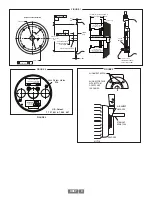

CAM SCREW ROTOR REMOVAL

Disengage the (2) cam screws by turning them counterclockwise

less than 1 full turn. The cam heads will visibly move away from the

shaft. Remove the rotor by hand by pulling it away from the motor. If

the rotor will not move, do NOT use a gear puller, and do not use a

heat gun. Instead, insert two M6 screws, >25mm length into the Jack

Screw Holes shown in Fig 2. Alternately tighten the screws to push the

rotor away from the motor and remove it.

LARGE BORE SET SCREW ROTOR REMOVAL

Disengage the (2) set screws by turning them counterclockwise until

removed from the rotor. Retain the set screws. Remove the rotor by

hand by pulling it away from the motor. If the rotor will not move, do

NOT use a gear puller, and do not use a heat gun. Instead, pry the

rotor away from the motor gently, being careful to only pry against the

rotor metal hub and not the magnetic outer strip.

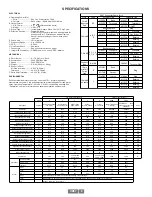

Equipment Needed for Installation

Provided

Optional

Not Provided

XR67 Stator/Housing

Socket Hd Cap Screw

3/8”-16 x 1.00” (4)

XR67 Rotor

Socket Set Screw

#M4 x 8mm (2) or Pre-

Installed Cam Screw

Thread locker (blue)

Extended Shaft Cover

w/ Screws 6-32 x

0.31” (4)

Lock Washers

Thru-Shaft Cover

w/ V-Ring Seal and

Silicone Lubricant

Phillips Screwdriver

2mm Hex Wrench

(T-Handle Style for Set

Screw Style Rotors)

3mm Hex Wrench

5/16” Hex Wrench

VARIATION > ± 15%

PHASE A

PHASE B

Содержание Avtron SMARTSafe XR67

Страница 13: ...XR67 13...

Страница 14: ...XR67 14...