9

© by NECTA VENDING SOLUTIONS SpA

0110 171-01

INSTALLATION

The machine installation and the following maintenance

operations should be carried out with the machine ener-

gised and therefore by qualified personnel, who are trained

in the correct use of the machine and are aware of the

specific risks of such condition.

The machine is not suitable for outdoor installation, it

must be installed in a dry room where the temperature

remains between 2° C and 32° C.

It cannot be positioned where water jets are used for

cleaning (e.g. in large kitchens, etc.).

The machine should be positioned with a maximum

inclination of 2°.

UNPACKING THE VENDING MACHINE

After removing the packing, ensure that the machine is

intact.

If the vending machine is found to be damaged, immedi-

ately inform the carrier and do not use the machine.

No packing elements (i.e. plastic bags, polystyrene

foam, nails, etc.) should be left within the reach of

children, as they are potentially dangerous.

Packing materials must be disposed of in authorised

containers and the recyclable ones must be recovered by

qualified companies.

CONNECTING TO THE POWER SUPPLY

The machine is designed to operate under single-phase

230 V~ voltage and is protected by 15 A fuses.

Before making the connection, ensure that the rating

corresponds to that of the power grid, and more specifi-

cally:

- the supply voltage rating must be within the range

recommended for the connection points;

- the main switch should be capable of withstanding the

peak load required, and at the same time ensure

proper omnipolar disconnection from the power grid

with an opening gap of the contacts of at least 3 mm.

The switch, the power outlet and the plug must be

located in an easily accessible position.

The electrical safety of the machine is ensured only when

it is correctly earthed according to the safety standards in

force.

This fundamental safety requirement must be duly

verified, and if in doubt the system must be carefully

tested by qualified technicians.

The power supply cable is of the type with a fixed plug. Any

replacement (see figure) should be done by qualified

personnel only, using exclusively cables of the type HO5

RN - F or HO5 V V-F or H07 RN-F with a section of 3x1-1.5

mm

2

.

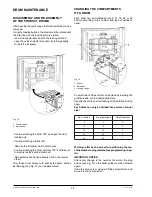

Fig. 7

1 - Cable from the mains

2 - Cable clamp

3 - Lift cover

Do not use adapters, multiple sockets and/or exten-

sions.

THE MANUFACTURER DECLINES ALL RESPONSI-

BILITY FOR ANY DAMAGE CAUSED BY NON-COM-

PLIANCE WITH THE ABOVE MENTIONED PRECAU-

TIONS.

INSTALLING THE PAYMENT SYSTEM

The machine is sold without payment system, there-

fore the installer of such a system is responsible for

any damage to the machine or to things and persons

caused by faulty installation.

- Install the desired coin mechanism according to the

appropriate instructions and make sure that the rel-

evant parameters are programmed correctly.

- adjust the selector opening lever bracket to allow

complete opening of the selector;

- adjust the coin chute according to the type of coin

mechanism installed.

Содержание StarFood

Страница 1: ...INSTALLATION OPERATING AND MAINTENANCE MANUAL UK English StarFood DOC NO H 171U 01 EDITION 2 2001 10...

Страница 2: ......

Страница 4: ......

Страница 56: ...NECTA VENDING SOLUTIONS SpA...

Страница 57: ...Star ood...

Страница 58: ...NECTA VENDING SOLUTIONS SpA...

Страница 59: ...Star ood...

Страница 60: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Страница 61: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Страница 62: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Страница 64: ......