7

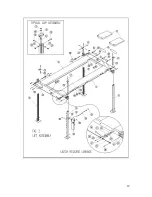

Find the leg caps

(4 each), 1/2” x 7” bolts (4 each), 1/2” x 1 1/4” bolts (4

each), 1/2” nuts (8 each) and 1/2 “ flat washers (16 each),

holes for cable face

towards the center of the lift. Secure the leg caps with

1/2” x 1 1/4” bolts

. Place

the bolts with washers in through channel and secure with washers and nuts on

the outside of the leg. Install the

1/2” x 7

” bolts through the leg and top cap.

Install from outside of the leg, and secure with a nut on the inside of the leg.

Tighten the

1 1/4” bolt

. Tighten the 7” bolt to a torque of 45 ft-lbs. Do not over

tighten the

7” bolt

, as this may warp the column channel and bind the guide

blocks.

1)

The cables are already strung and ready to attach to the top of legs. Before

doing this you must extend the chrome rod out of the cylinder far enough for the

cables to reach. If you have the lift on the lowest lock you will need to extend the

cable approximately 60 inches.

DO NOT USE THE POWER UNIT TO EXTEND THE CYLINDER

Make sure both parts on the cylinder are open to allow the easy flow of air.

Manually or with a device such as a come along, pull the cylinder out 60 inches.

Although the cylinder may be difficult to move at first, it is usually much easier

once you get the first movement.

If you have a compressor you can use air to extend the cylinder. Place the air

Into the back port, (the port away from the chrome rod) and blow air into the

cylinder.

After you have extended the chrome rod attach the cable to the top caps in the

legs. Make sure each cable is on the pulleys. Place both nuts on top of the top

cap and tighten them together.

Safety Latch Linkage Installation:

Locate and identify the components needed

to install the safety latch linkage rods. Install the spacers from on the straight

Содержание NSS8XLT

Страница 1: ...NSS8XLT NSS8XLT Installation Installation Manual Manual...

Страница 11: ...11...

Страница 12: ...12...

Страница 13: ...13...