8

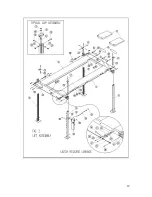

threaded end of the

1/2” x 50” (1/2” x 70” for the XLT) bent rod

and the

threaded end of the

1/2” x 126” straight safety latch linkage rod.

Install the

1/2” x 50” (70” XLT) bent safety latch linkage rod

into the main side

track adjacent to back end of the cylinder (opposite the cylinder rod). Safety latch

linkage rod should pass through guide tubes on underside of track.

Install the

1/2” x 126” straight safety latch linkage rod

into the main side track

from the opposite end. The rod should pass through two guides on the underside

of the main side track.

Attach the

71” hose

to the fitting on the power unit. Attach the other end of the

71” hose

to outside fitting in main side track. Attach hose from cylinder to track

fitting.

Place a funnel into vent cap hole and fill the tank with one of the following fluids:

AW-32

or

ISO-32

hydraulic oil.

Mobile DTE 24, or Texaco HD 32 DO NOT USE

DEXRON

®

IN THIS LIFT!

This tank will hold approximately 12 quarts.

Relocating or changing components may cause problems. Each component in

the system must be compatible; an undersized or restricted line will cause a drop

in pressure. All valve, pump, and hose connections should be sealed and/or

capped until just before use. All parts should be supplied from manufacture. Air

hoses can be used to clean fittings and other components. However, the air

supply must be filtered and dry to prevent contamination.

Most important -

cleanliness

- contamination is the most frequent cause of malfunction or failure

of hydraulic equipment.

Check Pulley Cover and Lock Collars:

Before proceeding, double check to

make sure the locking shaft collars for the crossrail cable pulleys are tight and

secure. Check the pulley cover (2-RIGHT and 2 LEFT) over the shaft located on

the pulley side of each crossrail. CHECK the pulley and cover are firm against

the locking shaft collar already in place. Check the additional lock collar on the

outside of the shaft is tight and secure. To prevent personal injury or death,

crossrail lock collars must be tight. If they are ever removed - always make sure

the locking shaft collars are tight and secure.

Check the crossrail locking assembly before use. Make sure all bolts and

collars are tight. The assembly is pre-installed from the factory but parts

may come loose during shipping.

After installation is completed, before start up, be sure to inspect and

tighten all bolts.

Содержание NSS8XLT

Страница 1: ...NSS8XLT NSS8XLT Installation Installation Manual Manual...

Страница 11: ...11...

Страница 12: ...12...

Страница 13: ...13...