10

2. Stand clear - Push the top UP button to raise vehicle to desired height. Push

the rod handle on the power unit to open release valve and lower tracks until it

stops, check the all four latches for full engagement in the rack on each leg.

3. To lower – push UP button to raise – rotate latch release rod handle and hold -

push rod handle on power unit to lower. Warning: Make sure all four latches

release – if not STOP, raise higher until latch is clear, if it does not work now the

hemin - tie rod end on that latch needs adjustment.

4. Any hydraulic oil leakage, unusual noise, or excessive wear must be fixed

before using lift.

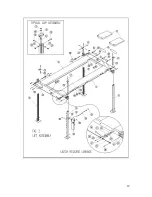

PRE OPERATION CHECK

The user should perform daily check.

ATTENTION! LOOK OUT!

Daily check of safety

latch system is very important - the discovery of device failure before needed could save

you from expensive property damage, lost production time, serious personal injury and

even death.

1. Check safety latches for free movement and

full engagement with rack.

2. Check hydraulic connections, and hoses for leakage.

3. Check cables for damage and that they are in the groove on cable sheave.

4. Check lock collars at all rollers and sheaves.

5. Check bolts, nuts, and screws and tighten.

6. Check wiring & switches for damage.

7. Keep base plate free of dirt, grease or any other corrosive substances.

Содержание NSS8XLT

Страница 1: ...NSS8XLT NSS8XLT Installation Installation Manual Manual...

Страница 11: ...11...

Страница 12: ...12...

Страница 13: ...13...