11

nitrogen gas generator

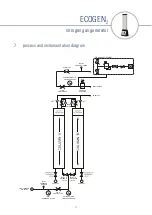

ECOGEN

2

4.3 start-up procedure

•

Ensure the inlet air temperature is between 5°C and 50°C (41°F and 122°F).

•

Ensure that all compressed air isolation valves are fully closed before operating.

•

Power up the generator, this will automatically start the generator and the display will illuminate.

•

Slowly open the air inlet valve

(see page 10/11)

and check for any leaks. Continue to open the air inlet valve until fully open.

•

Allow the generator to cycle at least two times.

•

Slowly open the ‘To buffer tank’ isolation valve

(see page 10/11)

until the buffer tank is at full pressure

(this will take a few cycles)

•

Slowly open the ‘From buffer tank’ isolation valve

(see page 10/11)

. At this point the generator control system will be able to

operate fully.

4.4 shutdown procedure

Please ensure this procedure is followed when shutting down the generator.

•

Do not turn off the power to the generator

•

Isolate all compressed air connections to the Nitrogen Generator and buffer vessel.

•

Allow the generator to continue to operate until the display indicates low pressure

•

Once low pressure is indicated the generator will depressurise itself through the exhaust valves.

•

Once the generator is fully depressurised the power can be switched off and the mains power isolated.

Beware

it can take up to

two

hours to clean the buffer tank, and hit required purity

CAUTION:

The generator may still retain trapped pressure!

Do not switch off or isolate the power to the generator before the generator is isolated from the

compressed air source and fully depressurised.

Pease ensure the correct shut down procedure is followed to shut the generator down.

Содержание ECO GEN2

Страница 19: ...nitrogen gas generator ECOGEN2 notes 19...

Страница 20: ...nitrogen gas generator ECOGEN2 notes 20...

Страница 21: ...nitrogen gas generator ECOGEN2 notes 21...