37

M1.2.TPT820.NLFREN 21112017

EN

9 Troubleshooting

Problem

Cause

Remedy

Engine fails to start

Spark plug wire disconnected.

Attach spark plug wire securely to spark

plug.

Out of fuel or stale fuel.

Fill with clean, fresh gasoline.

Throttle control lever not in correct

starting position.

Move throttle control lever to start

position.

Choke not in ON Position.

Throttle must be positioned at choke for

a cold start.

Blocked fuel line.

Clean the fuel line.

Fouled spark plug.

Clean, adjust gap, or replace.

Engine flooding.

Wait a few minutes to restart, but do not

prime.

Engine runs erratically

Spark plug wire loose.

Connect and tighten spark plug wire.

Unit running on CHOKE.

Move choke lever to OFF.

Blocked fuel line or stale fuel.

Clean fuel line. Fill tank with clean, fresh

gasoline.

Vent plugged.

Clear vent.

Water or dirt in fuel system.

Drain fuel tank. Refill with fresh fuel.

Dirty air cleaner.

Clean or replace air cleaner.

Engine overheats

Engine oil level low.

Fill crankcase with proper oil.

Dirty air cleaner.

Clean air cleaner.

Air flow restricted.

Remove housing and clean.

Engine will not stop when throttle control

is positioned at stop, or engine speed

does not increase properly when throttle

control is adjusted.

Debris interfering with throttle linkage.

Clean dirt and debris.

Compactor is difficult to control when

pounding (machine jumps or lurches

forward)

Too high engine speed on hard ground. Set the throttle lever at lower speed.

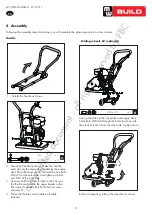

6. Carefully fold the upper handle down. Do not allow control cables to

become pinched or bent.

7. Store your plate compactor in upright position in a clean, dry building

that has good ventilation.

Do not store compactor with fuel in a non-ventilated

area where fuel fumes may reach flame, sparks, pilot

lights or any ignition sources.

Use only approved fuel containers.

Engine maintenance

Refer to the

Engine Manual

included in your plate

compactor for the information on engine

maintenance. Your engine manual provides detailed

information for performing the tasks.

1. Drain the fuel tank completely. Stored fuel

containing ethanol or MTBE can start to go stale

in 30 days. Stale fuel has high gum content and

can clog the carburetor and restrict fuel flow.

2. Start the engine and allo

w

it to run until it stops.

This ensures no fuel is left in the carburetor. Run

the engine until it stops. This helps prevent

deposits from forming inside the carburetor and

possible engine damage.

3. While the engine is still

w

arm, drain the oil from

the engine. R

efil

l

wit

h fresh oil of the grade

recommended in the Engine Manual.

4. Allo

w

the engine to cool. Remove the spark plug

and put 60 ml of SAE-30 of high quality motor

oil into the cylinder. Pull the starter rope

slow

ly

to distribute the oil. Replace the spark plug.

STORAGE

If the plate compactor

wil

l not be used for a period

longer than 30 days,

followi

ng the steps belo

w

to

prepare your unit for storage.

5. Use clean cloths to clean off the outside of the

compactor and to keep the air vents free of

obstructions.

6. Carefully fold the upper handle

down

. Do not

allo

w

control cables to become pinched or bent.

Remove the spark plug and drain all of

the oil from the cylinder before

attempting to start the unit after storage.

Do not use strong detergents or

petroleum

based

cleaners when

cleaning plastic parts. Chemicals can

damage plastics.

13

Vibratory Plate Compactor

7. Store your plate compactor in upright position

in a clean, dry building that has good ventilation.

Do not store compactor with fuel in a

non-ventilated area where fuel fumes

may reach

fl

ame, sparks, pilot lights

or any ignition sources .

Use only approved fuel containers.

8.

8.

See technical data for the

wei

ght of the machine.

To avoid burns or

fir

e hazards, let engine cool

before lifting / transporting machine or storing

indoors.

LIFTING / TRANSPORTING

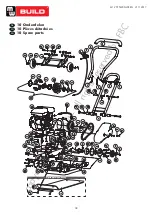

Apply pipe sealant to pipe plug and reinstall

into top of exciter housing.

Reinstall deck, V-belt(s) and belt guard.

Do not over

fil

l – over

fil

ling can result

in excessive temperatures in the exciter.

9.

The unit can be lifted by the handles in front and

back of the unit as shown.

copyrighted

document

- all

rights

reserved

by

FBC