make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Four (4)

relays are included for:

3-7.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

energize the battery charging alternator field.

3-7.2.2 Shutdown Relay; this relay is operated by the shutdown

circuits of the Control / Display Module and provides an output

that can be used to trip the generator circuit breaker on an

emergency shutdown.

3-7.2.3 Overspeed Relay; operates only on an Overspeed

shutdown. This relay provides an output to trip an air shut off

solenoid to close the air damper on a two-cycle engine.

3-7.2.4 Local Audible Alarm Relay; provides a contact closure

to operate a local audible alarm as required by NFPA- 110, Level

1 and Level 2.

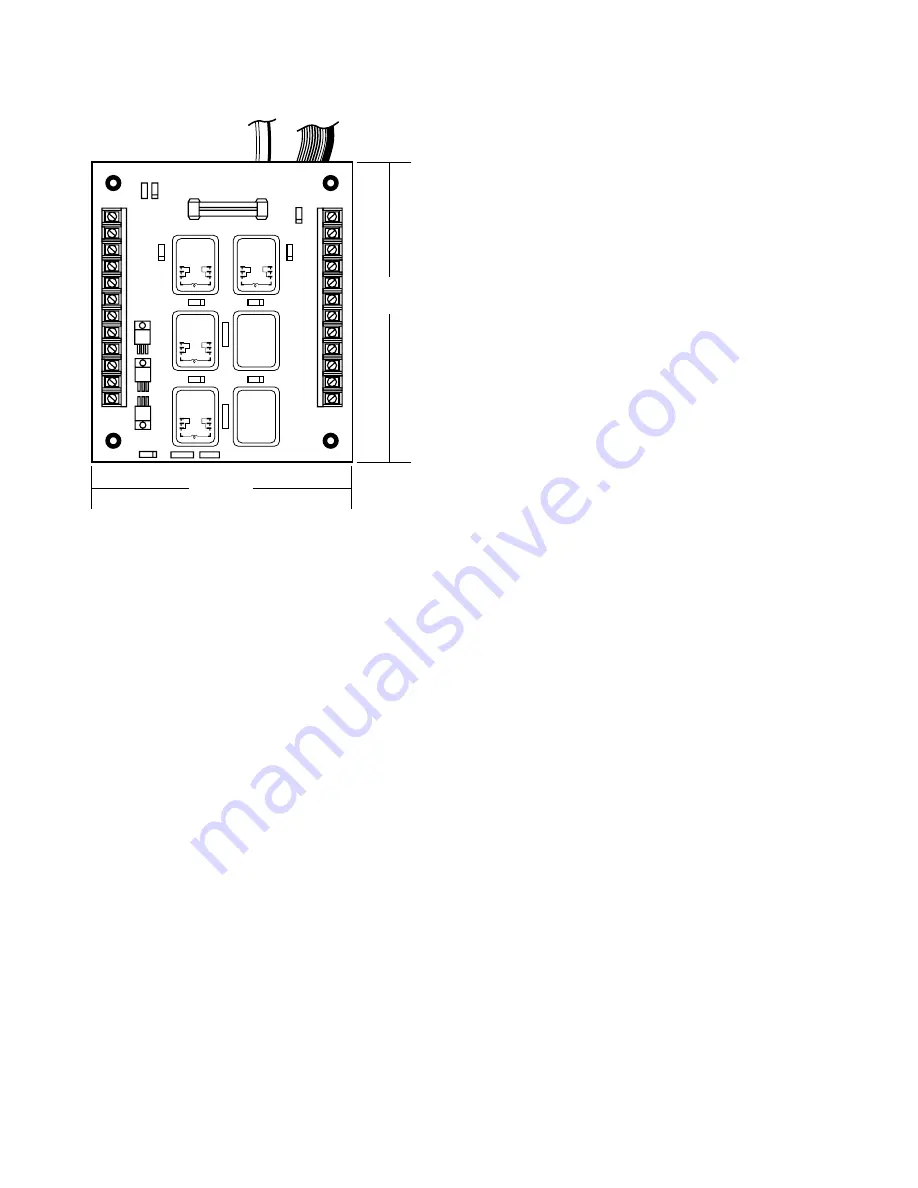

3-7.3 Status Signals. The relay module also includes three

outputs that can be used with external circuits for signaling or

control functions.

3-7.3.1 The Control On function at terminal 12 is on (closed to

negative) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

3-7.3.2 The System Ready signal at terminal 13 is on (closed

to negative) as long as the Mode Selector Switch is in either

Auto or Test and no shutdown TATTLETALE

®

circuit is

latched on. This can be used to signal that the generator

engine is ready to automatically start or is running in Test.

3-7.3.3 The Control On function at terminal 14 is on (closed to

positive) as long as the Mode Selector Switch is in either Auto

or Test. When the Mode Selector is turned Off, the Control On

signal is open. This can be used to signal switch position or to

reset an external circuit when the Mode Selector is turned Off.

Section 4: Installation

4-1 Location.

4-1.1 The A900 series is designed to mount in a

MURPHYMATIC

®

Generator Control panel with the Control /

Display module on the front panel and the Relay module on the

inside bottom surface. Other types of installation is possible as

long as the relationship of the two modules are maintained.

4-1.2 Clearance for Installation and Service; The modules must

be accessible for wiring to the terminal blocks and adjustment of

the user controls on the back of the Control / Display module.

Figure 4-1.2 shows the mounting dimensions and the minimum

clearances recommended for installation.

4-1.3 Wiring Terminals; Terminal blocks are provided on both

sides of the Control / Display enclosure and the Relay Module.

Torque all terminal screws to 12 inch pound maximum.

4-2 Wiring.

4-2.1 After the A900 has been located and installed, the wiring

connections can be made. This work should be done with all

electrical power disconnected from the engine. BE SURE THAT

THE BATTERY IS DISCONNECTED.

4-2.2 All electrical installation work should be done in

accordance with the National Electrical Code, NFPA-70, and all

applicable local codes.

4-2.3 In general, the following connections will be made:

(a) Battery positive and negative. An 8 A fuse or circuit

breaker must be provided to protect powered relay contact

circuits.

(b) Engine run device, such as a fuel shutoff solenoid.

(c) Engine speed sensor, such as a magnetic pickup or the

tachometer output of a battery charging alternator.

(d) Auxiliary crank disconnect device, such as a voltage

sensing relay contact wired to the generator output.

(e) Engine starter circuit; an auxiliary starter solenoid is

required to handle most starter solenoid requirements.

(f) Remote start contact. This is normally from the automatic

transfer switch but other sources are possible.

(g) Alarm and shutdown sensing switches as required.

4-2.3.1 The complete wiring of a Model A901 control is shown

in figure 4-2.3.1. Provision is made in the A900 series to

operate remote lights for all of the alarm and shutdown circuits

however these circuits do not have to be wired for the A900 to

function. Alarm input switches are not required but the alarm

circuits will not work without them.

4-2.3.2 Figure 4-2.3.2 is for wiring of the A902 control. The

same provisions as for the A901 are made.

4-2.3.3 The A903 wiring is shown in figure 4-2.3.3.

4-2.3.4 Wire Termination; the terminal blocks that are supplied

requires that all wires be terminated with #6 stud size forked

spade solderless wire connectors or stripped and inserted under

the captive terminal plates. Torque all terminal screws to 12

inch pound maximum.

4-2.3.5 All inductive loads (relays-soleniods-coils-etc.) that are

connected to the A900 must have reverse diodes wired across

the coil to supress reverse voltage that is generated whenever the

inductive load is de-energized. This will protect the electronic

components in the A900 and should prevent operating

malfunction due to noise. The “rule of thumb” for sizing the

reverse diode is to use one with a PIV (Peak Inverse Voltage)

rating equal to the operating voltage, or at least 100 volts and a

14

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

DC12V

DC12V

DC12V

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-7.2