Hand Extruder MEK-40,65 / MAK-40,65

Page 8/20

Issue 08.2008/Rev. 01

MUNSCH Kunststoff-Schweißtechnik GmbH

3 Transport and Storage

3.1 Transport

•

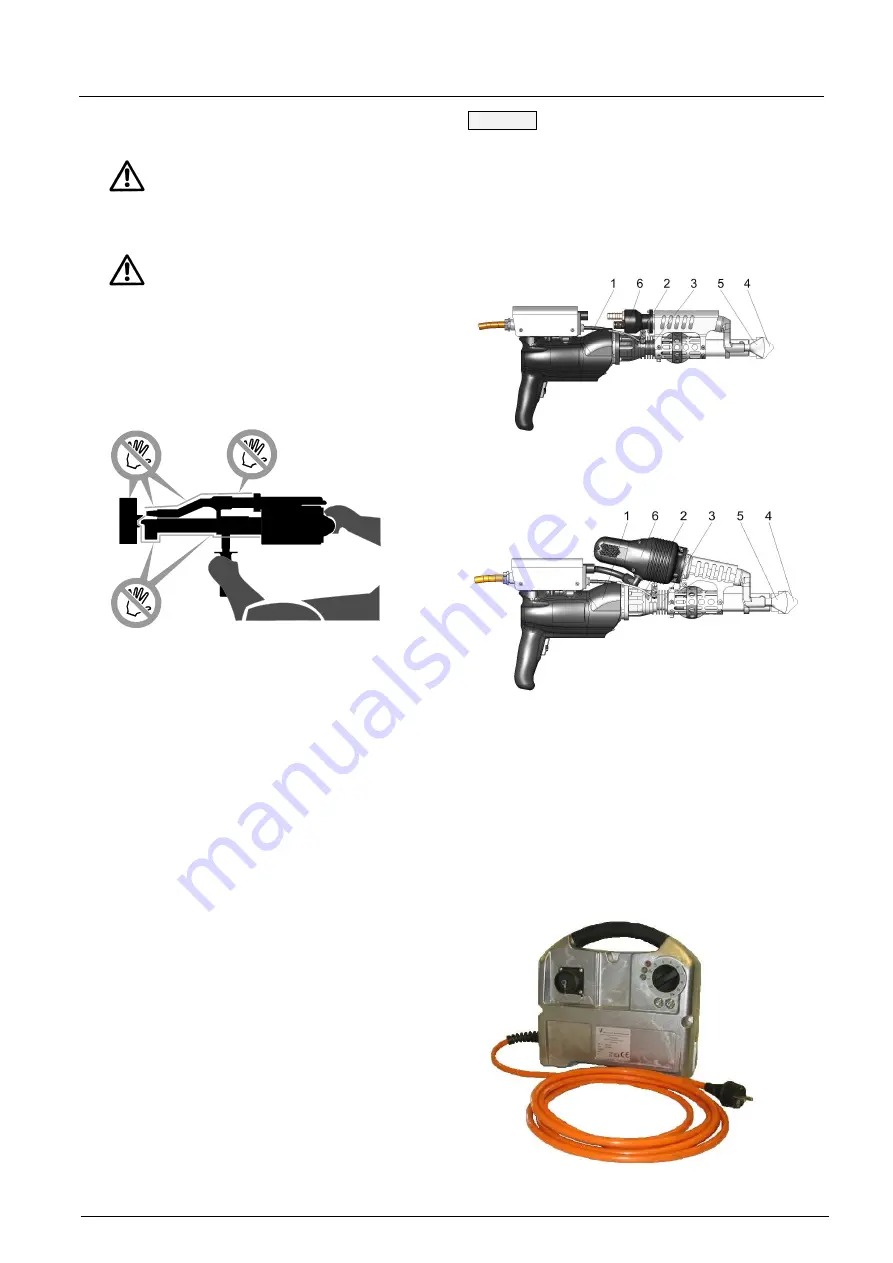

Before transport and storage, make

sure that the hand extruder has cooled down

to safe-to-touch temperature.

•

Hold and touch the hand extruder only on

the handles provided for this purpose.

Do not touch bare metal parts (including the hot

air hood) – whether with or without gloves – be-

fore having made sure that they are safe to touch.

These parts reach temperatures of up to 350 °C

during operation.

D02-0001

•

Always transport or store the hand extruder in

such a way as to preclude any mechanical loads

on the attachments.

If parts have been removed for transport pur-

poses, mount and fasten them carefully before

restarting the hand extruder!

Transport of the hand extruder in MUNSCH’s

original shipping case is recommended.

3.2 Storage

•

Store the hand extruder in a dry and frost-free

place.

•

Protect the hand extruder from unauthorized ac-

cess.

•

Special preservation is not required.

3.3 Return to Munsch

Should it become necessary to return the hand ex-

truder to MUNSCH Kunststoff-Schweißtechnik

GmbH, always use the original shipping case.

4 Product Description

4.1 Application range

The application range of the hand extruder is defined

by the data on the type tag and the service limits

indicated in these operating instructions.

CAUTION Operation of the hand extruder outside

the service limits stated in these operating instruc-

tions is subject to the Manufacturer’s prior approval.

4.2 General

Type MEK is a hand extruder with external air sup-

ply.

Type MAK is a hand extruder with integrated air

supply (Autoair).

Powerbox WX 2PBMU

Powerbox WX 2PBMU is required for the operation

of the hand extruder. It consists of a power pack, a

frequency inverter and an EMC filter. The drive

speed and hence, the melt throughput are set on the

Powerbox.

The Powerbox has three LEDs:

- red: undervoltage, defective

- yellow: temporary drive overload

- green: normal operation