Copyright Müller-Elektronik GmbH u. Co. UNI-Control S Installation and User´s Guide (01/95) Seite - 35 -

5

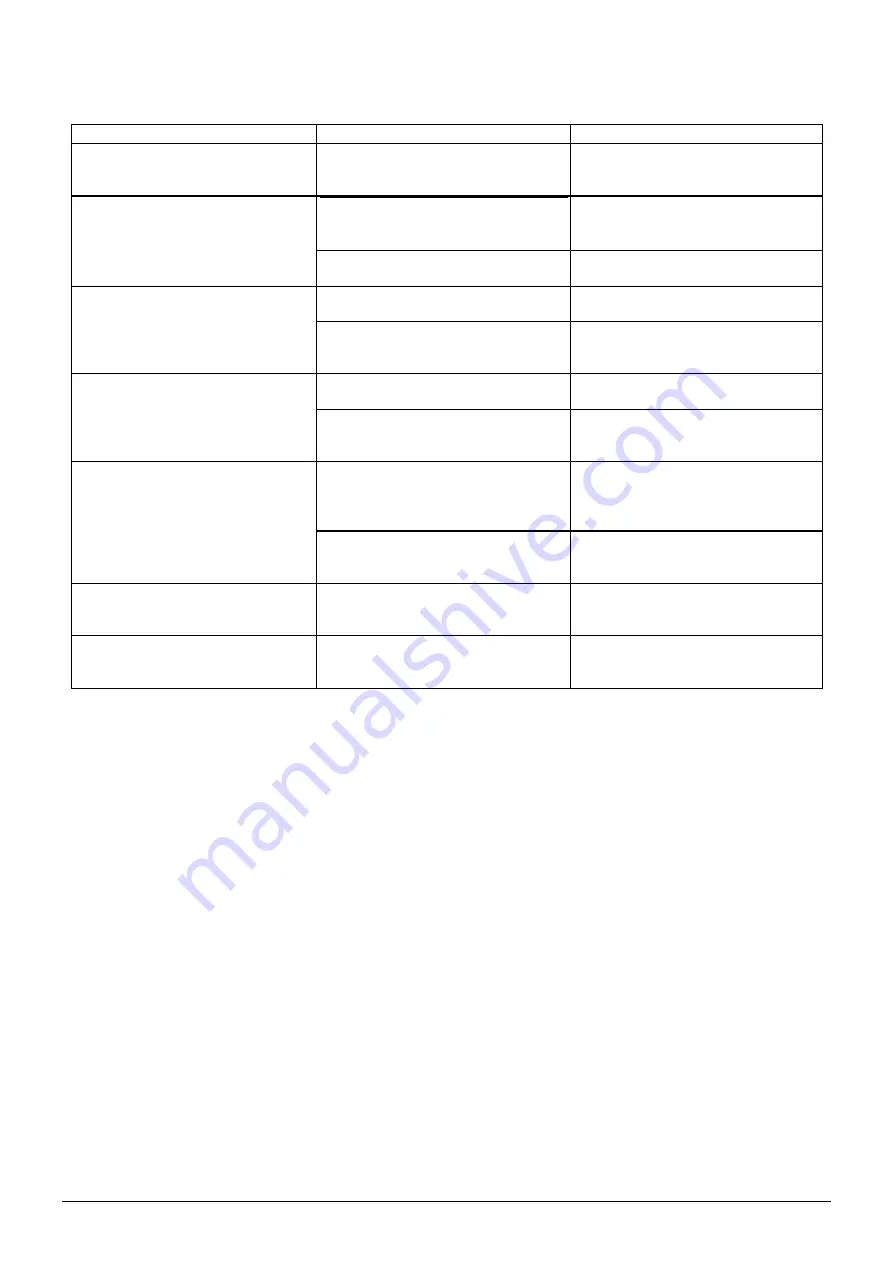

Error recovery

Error

Cause

Remedy

The display shows two straight

lines

Voltage too low

Check connection, take voltage

directly from the battery or from the

starter

Forward speed is not displayed

Signals are not reaching the

computer (The "wheel“ lamp is not

flashing)

Check sensors, cables and wiring

The pulse input is not calibrated

Carry out calibration

machine data

Area is not determined

Working width has not been entered

Enter working width

(machine data)

The working position is not

recognized by the computer

Depending on the installation, check

either the sensor or the working

position

Spread rate is not displayed

The figure impulse/kg has not been

entered

Enter impulse/l or impulse/kg

No signals are reaching the

computer from the corresponding

sensor

Check sensor

The intended spread rate has not

been reached. The current quantity

is below the pre-set rate. The horn

is sounding

The setting motor has been wrongly

poled. The rate is controlled

downwards instead of upwards

Repole the setting motor

The machine cannot transport the

pre-set amount

Change to a lower gear

The spread rate lies above the

pre-set rate. The horn is sounding

The setting motor has been wrongly

poled. The rate is controlled

upwards instead of downwards

Repole the setting motor

After switching on, the message

"memory error“ is displayed in

several languages

The memory contents have been

falsified, due to a faulty impulse

Switch the device on and off several

times

No liability is accepted for damages resulting from wrong dosage.

==================================================================

6

Maschine data

- Impulses/100 m (soft soil)

____________________

- Impulses/100m (medium soil)

____________________

- Impulses/100 m (firm soil)

____________________

- Working width.

____________________

- Factor impulses/litre

____________________

- Control constants

____________________

www.ROLTRONIK.pl