Page 504

3. If the maximum offset exceeds .the

Parallel dimension .015 inches, loos-

en the motor or pump and place thin

metal shims under the motor or pump

feet until the offset is set properly.

4. Torque down the motor or pump.

5. Recheck alignment.

The angular alignment dimension needs

to be 0.070 or less.

1. Using a micrometer or caliper, measure

from the outside of one flange to the

outside of the other at intervals around

the periphery of the coupling. DO NOT

rotate the coupling

2. Determine the maximum (B) and

minimum (C) dimensions. Refer to

Figure 2-4.

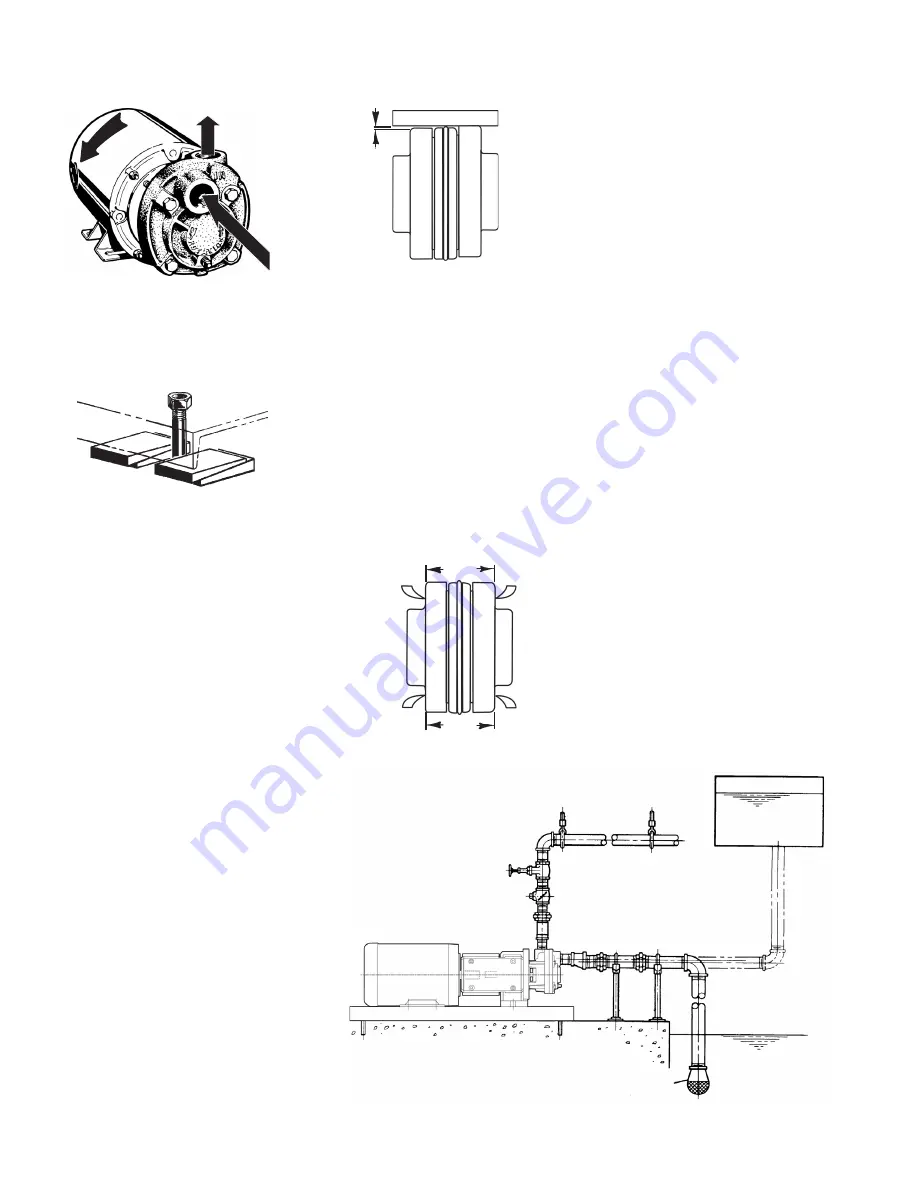

Figure 2-1

Figure 2-2

3. Support the baseplates on metal

shims or wedges having a small

taper. (Refer to Figure 2-2)

a. Place shims close to the founda-

tion bolts. (Refer to Figure 2-2)

Figure 2-3

A

4. Torque down the motor or pump.

5. Recheck the parallel alignment

above.

If the parallel (.015 inches) or angular

(.070 inches) misalignment is great, this

is an indication of baseplate distortion

and must be corrected first, refer to 2C

Leveling.

After all leveling and alignment opera-

tions have been completed, piping can

begin. After the piping has been com-

pleted, refer to 2E1 Piping Alignment.

Alignment of the unit must be checked

again to make certain that no piping

strains are causing distortion. After

approximately two weeks of operation,

check the alignment again to make

sure that temperature changes, piping

strain, or foundation variations have not

caused misalignment. If alignment has

been maintained over this period, the

pump and motor can be doweled to the

baseplate.

2E Piping

2E1 Piping Alignment

It is important that all piping be lined up

and not forced into place. It is recom-

mended that you begin piping at the

pump. If the lines are ended at the

pump, particularly if the last piece is cut

a little too short or long, the pump will

be forced to meet the pipe and strain or

distortion will result.

2E2 Piping Support

Never allow the pump to support piping.

Other means such as pipe hangers

and pipe supports should be used to

carry piping to avoid misalignment and

distortion. Consideration should be

given to thermally induced expansion

and contraction, particularly in long runs

of straight pipe.

Fasten Unit Securely to Foundation

Level Position

Gate Valve

Check Valve

Eccentric

Reducer

Increaser

Vent Plug /Drain

Pipe

Supports

Union

Union and Spool

Piece

Combination

Foot Valve and

Strainer

Area of Foot Valve 1 1/2

Times Pipe Area

Area of strainer 3 to 4

Times Pipe Area

Pipe Hangers

Suction Reservior

Long Suction Lines to have Continual Rise

From Source. Eliminate High Spots

Elbow 10 to 20 Pipe

Diameters from Pump

Suction

Arrangement of Suction Piping for

Head-on Suction

Figure 2-5

Figure 2-4

B

C

Outlet

Rotation

Inlet

b. Place shims close to where the

greatest weight is located.

4. Check the baseplate for distortion:

a. Place a straightedge along the

baseplate to determine if it is dis-

torted.

b. Adjust the shims until the

baseplate is not distorted.

5. Use a section of the pipe to de-

termine if the inlet and discharge

openings are vertical and located

properly.

6. Correct the positions, if necessary, by

adjusting the shims.

2D Alignment

Although flexible coupled pumps are

carefully aligned prior to crating and

shipping, it is almost a certainty that

strains imposed during transit have

altered the alignment. Complete the

following steps after the unit has been

placed on the foundation and leveled.

The standard coupling supplied by

MTH Pumps has an elastomer member

between two internal serrated flanges.

They have smooth outsides of equal

diameter. These surfaces are used for

alignment procedures.

To check the PARALLEL alignment:

(Refer to Figure 2-3)

1. Place a straightedge across the two

coupling flanges.

2. Measure the maximum offset (A),

Figure 2-3, at various points around

the periphery of the coupling. DO

NOT rotate the coupling.

3. If the difference between the

maximum and minimum exceeds the

Angular dimension (0.070 inches),

loosen the motor or pump and place

thin metal shims under the motor or

pump feet until the angular alignment

is correct.