18

The UV lamp is located on the underside of the homogeneous film to ensure that the UV light is

fully exposed to all space in the operating area. UV lamp has a delayed opening function, press the

UV light button, the operator quickly evacuate the scene, after 90S UV lamp is light to protect the

eyes and skin, and avoid injury caused byaccidental exposure.

E. fluorescent lamp

LED fluorescent lamp is adopted, located on the upper side of the homogeneous film to ensure that

the average illumination in the operating area is ≥ 500Lux.

F. Control panel

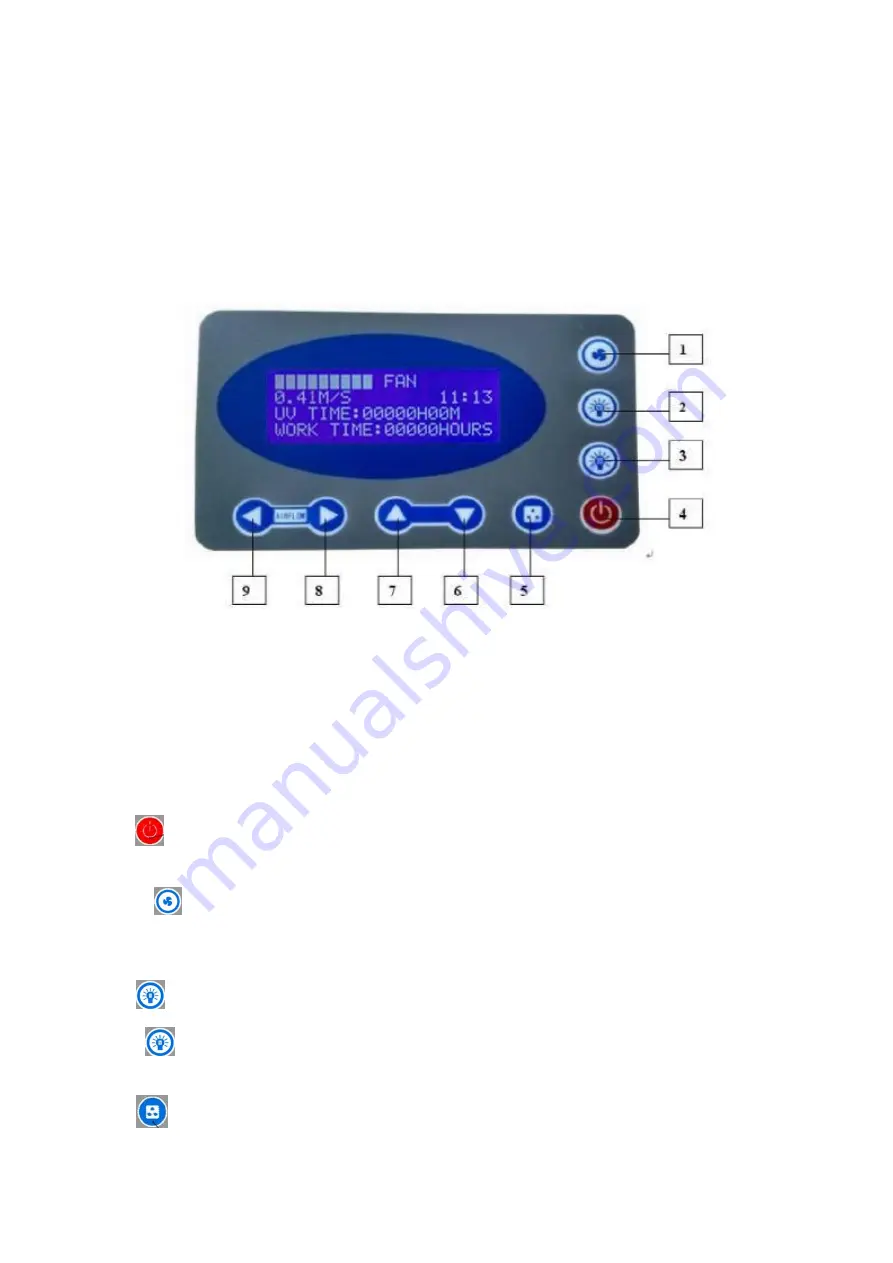

Figure 15

1. Fan button

2. Fluorescent lamp button 3. UV lamp button

4. Power button

5. Socket

button

6. UV lamp timing increase button 7. UV lamp timing decrease button

8. Airflow

decrease button

9. Airflow increase button

a) Gear display

The airflow velocity, gear, etc in working of the equipment can be known from the gear display

b) Touch the button lightly

The operation of the equipment is achieved by lightly touching the button.

(

1

)

“

”

:

Is the power button: the main switch to control the other function buttons. The system

can switchbetween standby mode and operating mode.

(

2

)

“

”Is the fan button: the control button of the working state of the fan. Fan has a

memory function, that is, at the time of starting up the fan, it can display the gear when it was shut

down last time, by which, there is no need to adjust the fan gear every time.

(

3

)

“

”The control button of the fluorescent lamp

(

4

)

“

”The control button of UV lamp.(UV lamp, fan , fluorescent lamp, that is when the

fluorescent lamp, fan are started up, UV lamp will be shut down automatically)

(

5

)

“

”Is the socket button: The socket will change between power on and power off

Содержание FH-12-DB

Страница 29: ...28 5 Appendix A Circuit diagram...