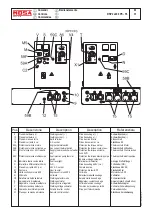

TROUBLE SHOOTING

DSP - EP5/EP7/ES

M

40.2

18/1

1/05 M40DSP/EP5-ES_GB

REV.3-09/07

PROBLEM

POSSIBLE CAUSE

WHAT TO DO

WELDING WITH V.R.D.

P10

The welding tension after

3 sec isn’t less enough

(plus in 12V dc)

1) Net R.C. defective or disconnected

from + or - welding socket

2) WDC defective.

1)

Check the net R.C. Check the connections.

2)

Replace

the WDC.

GENERETING

P1

Voltmeter shows no volta-

ge or low voltage but ac-

tual voltage at the sockets

is OK.

1) Voltmeter malfunction

1)

Replace

the voltmeter.

P2

No three-phase voltage

present at the socket(s).

1) Differential switch not inserted

2) Differential switch malfunction

1)

Turn on

the switch.

2)

Replace

the

switch.

P3

No single

phase voltage

one socket but voltmeter

reading is normal and

there is voltage on the

other sockets.

1) Intervention of thermal switch due

to excessive current.

2) Thermal switch malfunction.

1)

Push in

the thermal switch.

2)

Replace

the thermal switch.

P4

No voltage present.

(See problem P9)

1) Short circuit present on the gene-

rator outputs.

1)

Disconnect

all outputs on the generator except for those on the con-

densers and re-start machine; check for voltage on condensers.

MOTOR

P1

The engine does not start

or stops immediately after

startup.

1) Low battery voltage, battery dead

or defective.

2) Presence of air in the fuel supply

circuit.

3) Circuit breaker engine protection

4) Engine solenoid

1)

Check the warning light “state of the battery”: - Green colour: battery

OK - Black colour: battery to be recharged - White colour: battery to be

replaced -

DO NOT OPEN THE BATTERY.

2) Carry out de-aeration on the fuel system. See engine operating manual.

3) Insert the circuit breaker. In case the problem persists, check the electrical

circuit and eliminate the problem. Call an authorised service centre.

4) See engine manual

P2

Engine stops due to

intervention of EP5/EP7/

ES.

1) Engine temperature too high or

insufficient oil pressure.

2) High temperature sensor or oil

pressure defective.

3) EP5/EP7/ES protection defective

1)

Check

oil level.

2)

Replace

the malfunctioning sensor.

3)

Replace

the protection.

P3

The battery is not

charged.

1) Battery charger alternator defecti-

ve.

2) Battery charger warning light de-

fective.

1)

Replace

2)

Replace

P4

For other problems, refer

to the attached engine

manual

Содержание DSP 2x400 PS-PL

Страница 38: ...DSP 2x400 PSX REV 0 11 05 M 53 Dimensioni Abmessungen Dimension 18 11 05 88412 I...

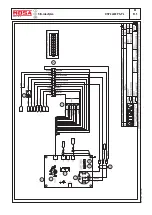

Страница 42: ...DSP 2x400 PS PL REV 0 11 05 M 61 2 Stromlaufplan 28 11 05 78413 D...

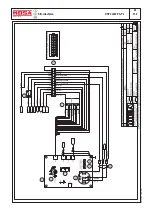

Страница 43: ...DSP 2x400 PS PL REV 1 02 11 M 61 3 Stromlaufplan 28 11 05 78413 D...

Страница 44: ...DSP 2x400 PS PL REV 1 02 11 M 61 4 Stromlaufplan 28 11 05 78413 D...

Страница 45: ...DSP 2x400 PS PL REV 1 02 11 M 61 5 Stromlaufplan 28 11 05 78413 D...

Страница 46: ...DSP 2x400 PS PL REV 1 02 11 M 61 6 Stromlaufplan 28 11 05 78413 D...