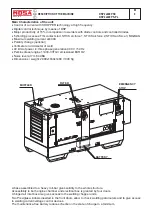

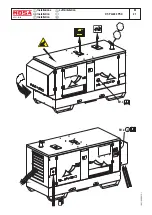

A base assembled to a heavy roll-bar gives solidity to the whole structure.

Accessibility to both engine chamber and electrical box is granted by four doors.

A hinged air inlet box also gives access to the welding chopper units.

Two Plexiglas windows inserted in the front doors allow to check welding parameters and to give access

to welding current/voltage control devices.

The maintenance-free battery reduces checks on the state of charge to a minimum.

DESCRIPTION OF THE MACHINE

DSP 2x400 PSX

DSP 2x400 PS-PL

M

0

REV.0-02/11

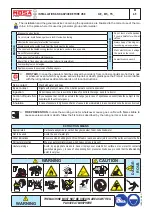

Main Characteristics of the unit:

•

Control of current with CHOPPER technology at high frequency

•

Digital control technique by means of DSP

•

Major productivity of 15% in comparison to welders with diode controls and controlled diodes

•

5 Welding processes: TIG contact start, STICK arcforce 1, STICK arcforce 2, STICK arcforce 3, MIGMAG

•

Maximum welding current 2x400A

•

Polarity change (optional)

•

Voltmeter and Ammeter of weld

•

40 kVA of power in three phase generation 400 V / 50 Hz

•

Perkins diesel engine 1103C-33TG3 emissioned EURO 2

•

Noise level at 7m 64 dBA

•

Dimensions / weight: 2490x1030x1480 /1300 Kg

EMERGENCY

STOP

BATTERY

FILTER

MUFFLER

Содержание DSP 2x400 PS-PL

Страница 38: ...DSP 2x400 PSX REV 0 11 05 M 53 Dimensioni Abmessungen Dimension 18 11 05 88412 I...

Страница 42: ...DSP 2x400 PS PL REV 0 11 05 M 61 2 Stromlaufplan 28 11 05 78413 D...

Страница 43: ...DSP 2x400 PS PL REV 1 02 11 M 61 3 Stromlaufplan 28 11 05 78413 D...

Страница 44: ...DSP 2x400 PS PL REV 1 02 11 M 61 4 Stromlaufplan 28 11 05 78413 D...

Страница 45: ...DSP 2x400 PS PL REV 1 02 11 M 61 5 Stromlaufplan 28 11 05 78413 D...

Страница 46: ...DSP 2x400 PS PL REV 1 02 11 M 61 6 Stromlaufplan 28 11 05 78413 D...