Quality Crimp Handbook

Order No 63800-0029

Release Date:09-04-03

UNCONTROLLED COPY

Page 16 of 24

Revision: B

Revision Date: 10-07-05

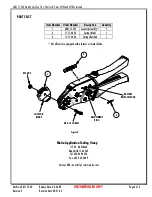

Figure 9-1

IRREGULAR INSULATION CUT

Figure 9-2

CUT STRANDS

Figure 9-3

PULLED STRANDS

Figure 9-4

WIRE LENGTH VARIABILITY OR WRONG STRIP LENGTH

SECTION 9

TROUBLE SHOOTING

Wire Preparation

Symptom

Cause

Solution

Worn tooling

Replace tooling

Irregular insulation cut

(Figure 9-1)

Wire cut depth too shallow

Adjust cut depth

Damaged tooling

Replace tooling

Cut depth too deep

Adjust cut depth

Cut or nicked strands

(Figure 9-2)

Conductor not on wire center

Contact wire supplier

Worn tooling

Replace tooling

Irregular conductor cut-pulled strands

(Figure 9-3)

Wire cut depth too shallow

Adjust cut depth

Wire drive rollers/belts worn

Replace belts/rollers

Insulation durometer too hard

Increase drive pressure

Wire length variability too high

(Figure 9-4)

Wire straightener too loose or tight

Adjust wire straightener

Wrong strip length (Figure 9-4)

Incorrect setup

Re-setup tooling