Quality Crimp Handbook

Order No 63800-0029

Release Date:09-04-03

UNCONTROLLED COPY

Page 15 of 24

Revision: B

Revision Date: 10-07-05

using two types of gauges. Molex recommends a gauge

capability study to identify what part of the variability is

coming from measurement error. Micro-terminals

crimped to small wire sizes need a tight crimp height

range to maintain pull force. The variability from

measurement error can keep CpKs low.

The capability of the crimping tools needs to be re-confirmed

if the production data is significantly different from the

capability study.

Production

Before the tool is ready for production, the level of

capability needs to be established. Many harness

manufacturers run only a few hundred or few thousand

wires at one time. In this case, it is not practical or

economical to run a twenty-five-piece capability with

every set-up.

Visual Inspection

It needs to be standard operating procedure for the

operator to manually fan each bundle of crimped wires

and visually check bell mouth, conductor brush, insulation

position, cut-off tab length, and insulation crimp.

Control Charting

Crimp height is typically control charted because it is a

quick nondestructive measurement and is critical for the

termination's electrical and mechanical reliability. There

are three primary purposes for control charting. One, the

number of setup samples is usually small, with limited

statistical value. Two, since special cause effects on a

process are irregular and unpredictable; it is necessary to

be able to catch changes in the process as soon as they

occur. This prevents thousands of terminations from being

scrapped after the run is over. Three, and most important,

this data is necessary to assess and improve the crimp

process.

Once the tooling process is setup and the wire size does

not change, keep one control chart for wire color changes,

wire length changes, terminal material changes, or setup

adjustments. Record the data point on the chart before

making a crimp height adjustment. If data is recorded

after each adjustment, the process is likely to assume

control and provide little data for improving the process.

The operator needs to make as many notes as possible on

the chart. The only truly effective and economically

sensible way to manage a manufacturing process is to

understand, monitor and reduce sources of variability that

are inherent to the process itself. Every minute required

for setup or adjustments is unproductive.

What does this sample chart tell us?

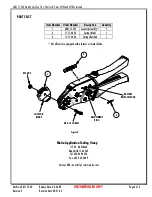

X and R Chart

Control limit for sample of 5 = Avg

(Avg of 5readings) + .577 x Avg (Ranges)

It indicates that a process shift occurred between

measurement 12 and 13. This type of shift could occur

due to a change in wire, a change in terminal lots, a jam

in the machine that damaged the tooling, a change in

operators, or an adjustment to the insulation crimp. Since

the measurements are still within specification, would you

stop production to adjust crimp height?

A shift in the process due to a change in material may

warrant a crimp height adjustment. A shift after a jam

would not indicate an adjustment, but a close evaluation

of the tooling. A shift in the process between operators

would not indicate an adjustment, but an evaluation of

measurement capability. The purpose of a control chart is

to identify what caused the shift in process to determine if

an adjustment to the process is needed.