Quality Crimp Handbook

Order No 63800-0029

Release Date:09-04-03

UNCONTROLLED COPY

Page 20 of 24

Revision: B

Revision Date: 10-07-05

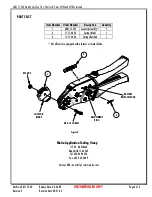

Figure 9-25

OPTIMAL CRIMP HEIGHT CHART

Figure 9-26

CRIMP HEIGHT OFF TARGET

Figure 9-27

CRIMP HEIGHT VARIABILITY TOO HIGH

Crimp Height

Symptom

Cause

Solution

Changed wire type vendor or stranding

Changed insulation color or durometer

Changed crimp tooling

Changed crimp press (shut height)

Changed press type (manufacturer)

Changed terminal reel (lot code)

Changed tooling set-up

Crimp height off target

(Figure 9-26)

Damaged or worn tooling

Adjust tooling back to target

Wire variability

Terminal variability

Inspect incoming product

Damaged, loose or worn tooling

Tooling replacement or tightening

Measurement error

Gauge capability analysis

Terminal spring-back too great, over crimping

Crimp height adjustment

Crimp height variability too high

(Figure 9-27)

Cut or missing wire strands

Stripping process adjustment