Troubleshooting

Series 203 Variable Leak Valve Installation and Operating Instructions

7

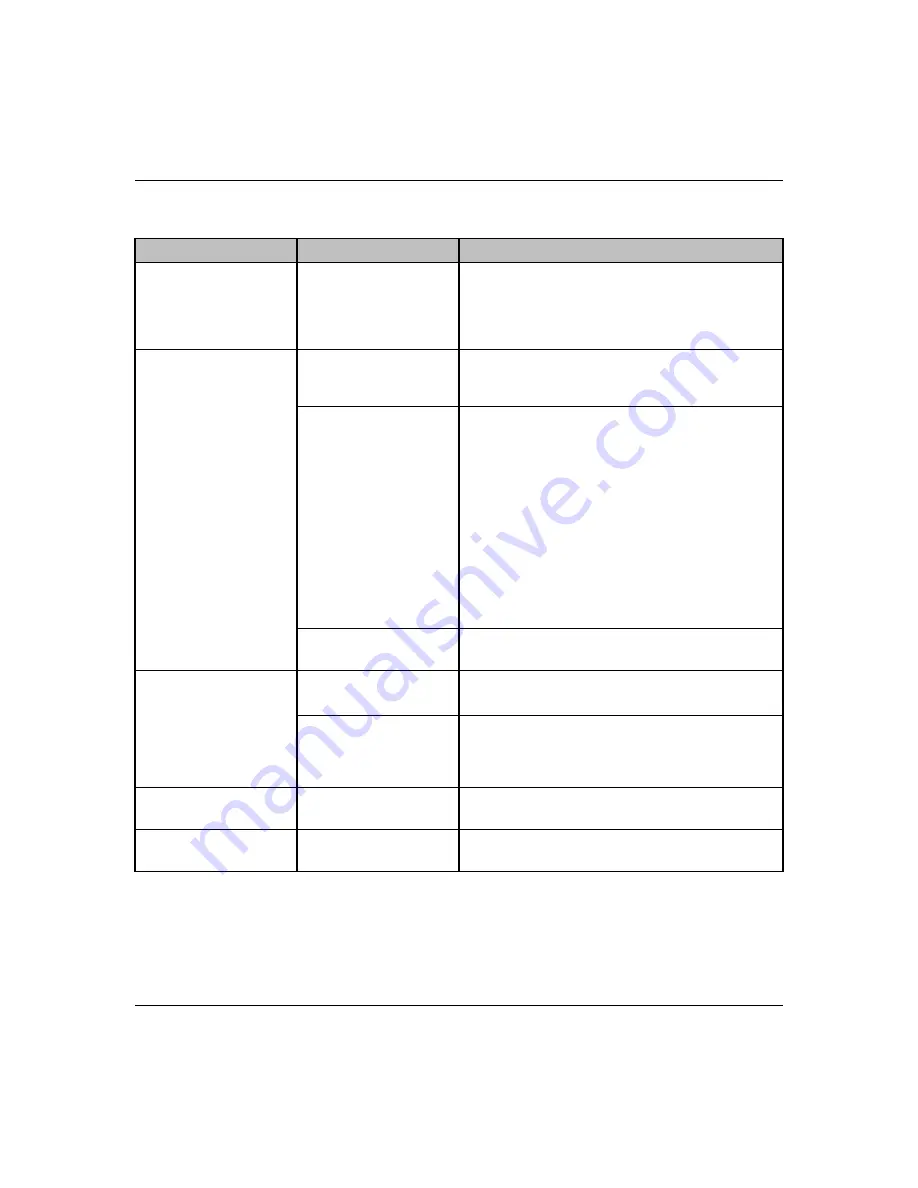

Symptoms, Causes, and Remedies

Symptom

Cause

Remedy

Leak has only on or off

properties. Does not give

smooth continuous control.

A liquid film on the sealing

surfaces produced by

allowing moist or vapor

laden gases to flow through

the Leak.

A brief vacuum bakeout at 200 to 300 ° C for a few hours.

Leak will not seal.

Insufficient thrust, clutch

slips before seal is attained.

Remove the driver handle and tighten the clutch set screw.

After the Leak is sealed, adjust the clutch to slip about 10

counter numbers below the sealed position.

Insufficient thrust, driver

dirty.

Remove the driver. Remove the clutch. Remove the

retaining rings holding the drive shaft bearings in place.

Remove the bearings and the worm shaft. The drive screw

worm gear assembly should now be carefully unscrewed.

Clean the drive screw threads with a solvent such as

chlorothene. Do not allow the drive screw worm gear

assembly to come in contact with heat. Clean the worm. Do

not clean the bearings. Relubricate the

contact surfaces of the worm and gear and drive screw with

molybdenum disulfide. Reassemble. Remove the retracting

screw. Loosen the set screw in the aluminum bushing and

rotate one-eighth turn. Tighten set screw and replace the

retracting screw. Test the valve for control. Repeat as

necessary until smooth action is obtained.

Sealing surfaces

contaminated.

Replace Leak Valve body. Glass particles, lint, metal chips

and dust cannot usually be removed.

Leak momentarily opens or

closes in reverse reaction to

the turning of the driver

handle.

Misalignment of Driver

Assembly and Leak Valve.

Re-attach the Driver and Leak Valve, tighten the mounting

screws evenly.

Driver Assembly parts out of

alignment.

Remove the retracting screw. Loosen the set screw in the

aluminum bushing and rotate one-eighth turn. Tighten set

screw and replace the retracting screw. Test the valve for

control. Repeat as necessary until smooth action is obtained.

Body mounting screws stick

after bakeout.

Lubrication has evaporated.

Place drops of penetrating oil on each screw and let soak for

10 minutes.

Retracting screw strips out

of nosepiece.

Retracting screw not

properly seated.

Always make certain retracting screw is completely engaged

before operating valve.

Содержание Granville-Phillips 203 Series

Страница 2: ......

Страница 4: ......

Страница 6: ...ii Series 203 Variable Leak Valve Installation and Operating Instructions...

Страница 15: ......