3-2. FLARE CONNECTION

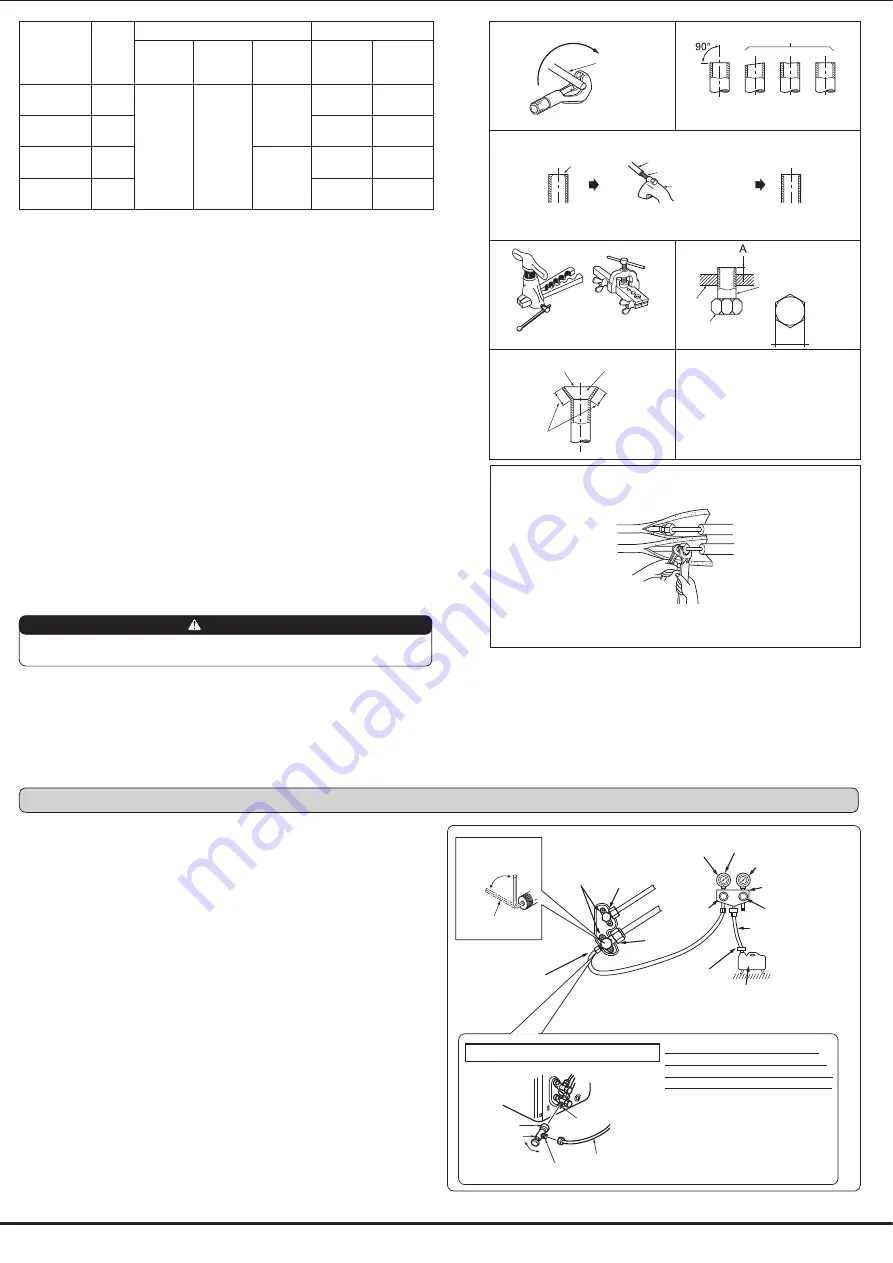

1) Cut the copper pipe as straight as possible with a pipe cutter. (Fig. 1, 2)

2) Remove all burrs from the cut section of the pipe, ensuring that precautions are taken to

avoid getting metal shavings into the piping. (Fig. 3)

Y$Z"M\ O&"&&

4) Flaring work (Fig. 4, 5). Firmly hold copper pipe in the dimension shown in the table. Select

A inch (mm) from the table according to the tool you use.

5) Check

^"& \ %

QN\ NMONN & &

3-3. PIPE CONNECTION

% \ _ & ; ;M

`N O\ " +M +; N

z & &&{ ; &&" +

in burns or frostbite.

Indoor unit connection

Connect both liquid and gas piping to indoor unit.

&&+ NN |$\ N&&{ &&+-

frigeration oil on screw threads. Excessive tightening torque will result in damage on the

screw.

@O OYN\

}_ ; ;M N~O

=M " \

Outdoor unit connection

Connect pipes to stop valve pipe joint of the outdoor unit following the same procedure

detailed in Indoor unit connection.

%O _&

3-4. INSULATION AND TAPING

1) Cover piping joints with pipe cover.

2) For outdoor unit side, insulate the piping, including valves.

3) Apply piping tape (G) starting from the connection on the outdoor unit.

`&& ; O"&

"+ O && &M -

tion.

Copper

pipe

Good

Tilted

No good

Fig. 1

Fig. 2

Burr

Copper pipe

Spare reamer

Pipe cutter

Fig. 4

Fig. 3

Smooth all around

Even length

all around

Inside is shin-

ing without any

scratches.

Fig. 5

Fig. 6

Flare nut

Die

Copper pipe

Clutch type

Flaring tool

Wing nut type

Pipe diameter

inch (mm)

B

inch

(mm)

A inch (mm)

Tightening torque

Clutch

type tool

for R410A

Clutch

type tool

for R22

Wing nut

type tool

for R22

ft-lb

N"$

"

ø 1/4 (6.35)

21/32

(17)

0 to 0.02

(0 to 0.5)

0.04 to 0.06

(1.0 to 1.5)

0.06 to 0.08

(1.5 to 2.0)

10 to 13

(140 to 180)

13.7 to 17.7

ø 3/8 (9.52)

7/8 (22)

25 to 30

(350 to 420)

34.3 to 41.2

ø 1/2 (12.7)

1-1/32

(26)

0.08 to 0.10

(2.0 to 2.5)

36 to 42

(500 to 575)

49.0 to 56.4

ø 5/8 (15.88)

1-5/32

(29)

54 to 58

(750 to 800)

73.5 to 78.4

4-1. PURGING PROCEDURES AND LEAK TEST

1) Remove service port caps from stop valves on both sides of refrigerant lines. (The stop

valves are fully closed when shipped.) Leave closed.

2) Connect gauge manifold to ports of stop valves.

3) Evacuate the system to 4000 microns from both service valves. System manifold gauges

must not be used to measure vacuum. A micron gauge must be used at all times. Break

the vacuum with Nitrogen(N2) into the discharge service valve to 0 PSIG.

4) Evacuate the system to 1500 microns. Break the vacuum with Nitrogen(N2) into the

discharge service valve to 0 PSIG.

5) Evacuate the system to 500 microns.

6) Close gauge manifold valves, stop the pump, and conduct a 30 minute rise test.

7) System should hold 500 microns for a minimum of 1 hour.

8) Fully open all stop valves on both sides of gas pipe and liquid pipe. Operating without

fully opening lowers the performance and this causes trouble.

9) Refer to 1-3 and charge the prescribed amount of additional refrigerant if needed. Be

sure to charge slowly with liquid refrigerant. Otherwise composition of the refrigerant in

the system may be changed and affect performance of the air conditioner.

10) Remove gauge manifolds and replace service port caps and tighten.

11) Leak test

Uneven Burred

WARNING

When installing the unit, securely connect the refrigerant pipes before starting the

compressor.

B

Stop valve for

GAS

Stop valve cap

(Torque 15 to

22 ft-lb, 19.6 to

?"O?!!

Y!!N"$

Vacuum pump (or the vacuum

pump with the function to

&M; \$

Gauge manifold valve

(for R410A)

Compound pressure gauge

(for R410A)

–14.7 psi [Gauge]

!!& $

Handle

Low

Handle High

Adapter for

preventing the

; \

Charge hose

(for R410A)

*Close

*Open

Hexagonal wrench

Precautions when using the control valve

When attaching the control valve

to the service port, valve core may

deform or loosen if excess pressure

is applied. This may cause gas leak.

Service port

Charge hose

Body

Close

Open

Control valve

A

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

then tighten part A. Do not tighten

part A or turn the body when valve

core is in open position.

Service port cap

(Torque 10 to 13 ft-Ib,

Y"O140

to 180 kgfcm)

*4 to 5 turns

Stop valve for LIQUID

Pressure gauge

(for R410A)

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN