10

ENGLISH

•

Make sure to use new refrigerant piping.

- When using the existing piping which used R22, take care of the

following points.

• Replace the flare nut with that is attached to the product. Flare

section must be finished with the flare processing.

• Use of piping with thin wall should be avoided.

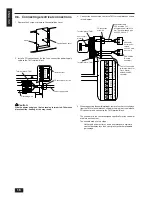

* When applying the flare processing for the refrigerant R410A using conventional

tools, conduct the work referring to the above. If you use the copper pipe gauge

for the adjustment of protrusion margin, you can secure the dimension A.

Pipe Dia. (mm)

ø6.35 (1/4”)

ø9.52 (3/8”)

ø12.7 (1/2”)

ø15.88 (5/8”)

0~0.5

0~0.5

0~0.5

0~0.5

1.0~1.5

1.0~1.5

1.0~1.5

1.0~1.5

1.5~2.0

1.5~2.0

1.5~2.5

1.5~2.5

R410A Flare Tool When using conventional flare tool (R22/R407C)

Dimension A (mm)

Rigid (clutch type)

Imperial (wing nut) type

Dice

Copper pipe

A

ø

B

R

0.4

~

R

0.8

Copper Pipe O.D.

ø6.35

ø9.52

ø12.7

ø15.88

8.7~9.1

12.8~13.2

16.2~16.6

19.3~19.7

Flare Dimension

Dimension øB (mm)

Coat small amount of ester oil, ether oil or hard alkylbenzen oil over

the entire periphery of flare seat surface.

* Do not coat at the threaded section.

(Otherwise, you cannot lock the flare nut securely.)

* Make sure to use only the flare nut attached to the main unit. (Off-the-shelf

product could be cracked.)

Содержание Fresh Master GUF-100RD3

Страница 22: ...22 ENGLISH ...