FrameMaker Ver5.5E(PC) CF1501/CF2001 SWITCHES ON PWBs/TECH. REP. SETTINGS

00.11.30

S-21

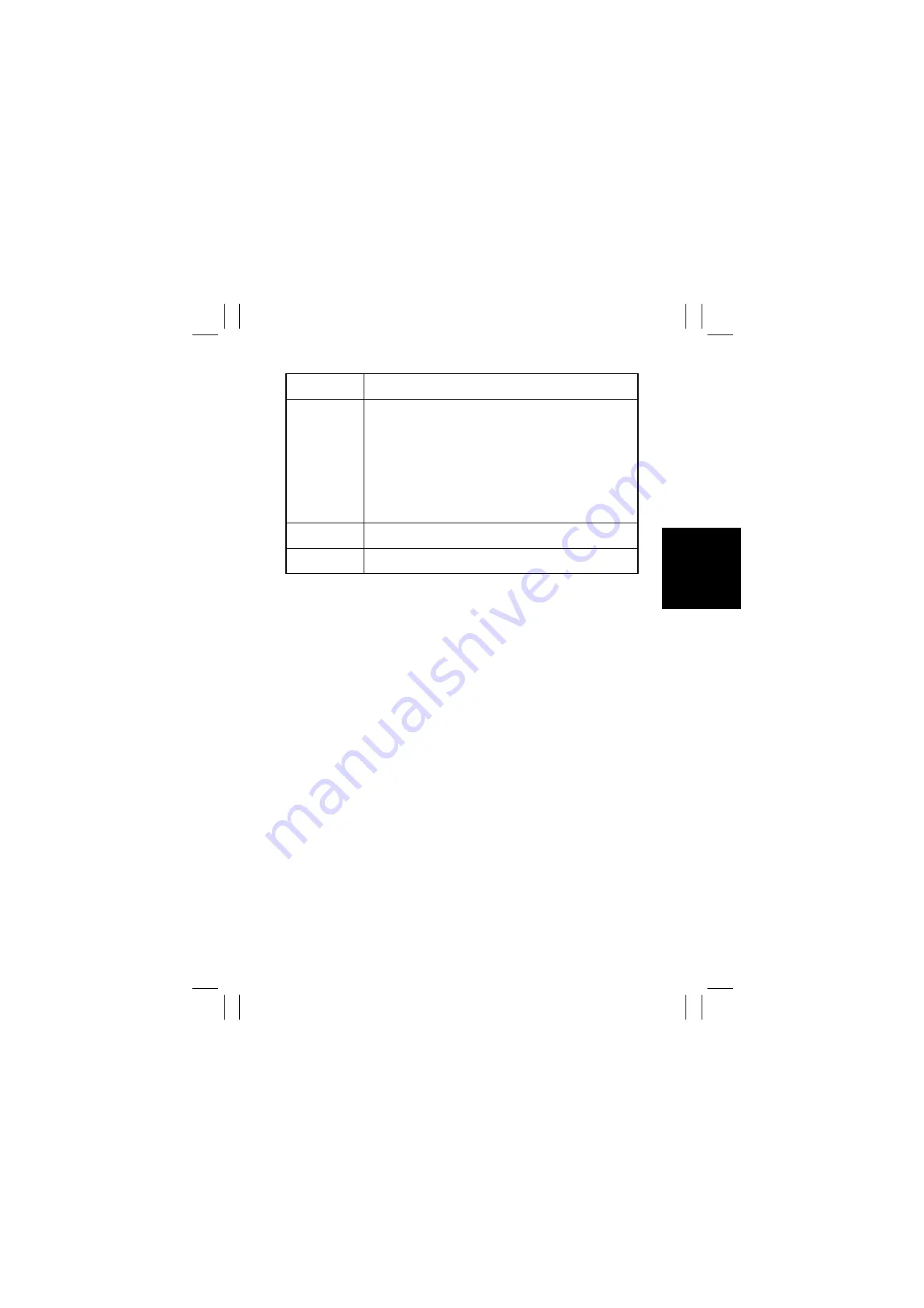

Touch Panel

Display

Setting

Color Shift

Correction

Color Shift Correction (C)

Correct (fine-adjust) color shift of the cyan image in each of X, Y, and

θ

directions.

Color Shift Correction (M)

Correct (fine-adjust) color shift of the magenta image in each of X, Y,

and

θ

directions.

Color Shift Correction (Y)

Correct (fine-adjust) color shift of the yellow image in each of X, Y,

and

θ

directions.

Color Shift Correction (Bk)

Correct (fine-adjust) color shift of the black image in the

θ

direction.

LPH Rank

This mode is for factory adjustment only and should NOT be used.

It is confirmed that the numerical value is “0”.

Staple/Hole-Punch The staple position or the punch hole position is confirmed.

✽

The content changes by the installed exit option.

Содержание CF1501

Страница 3: ...FrameMaker Ver5 5E PC CF1501 CF2001 GENERAL 00 12 15 GENERAL ...

Страница 12: ...FrameMaker Ver5 5E PC CF1501 CF2001 MECHANICAL ELECTRICAL 00 12 15 MECHANICAL ELECTRICAL ...

Страница 129: ...FrameMaker Ver 5 5E PC CF1501 CF2001 DIS REASSEMBLY ADJUSTMENT 00 12 25 DIS REASSEMBLY ADJUSTMENT 18605 ...