7-2

Troubleshooting

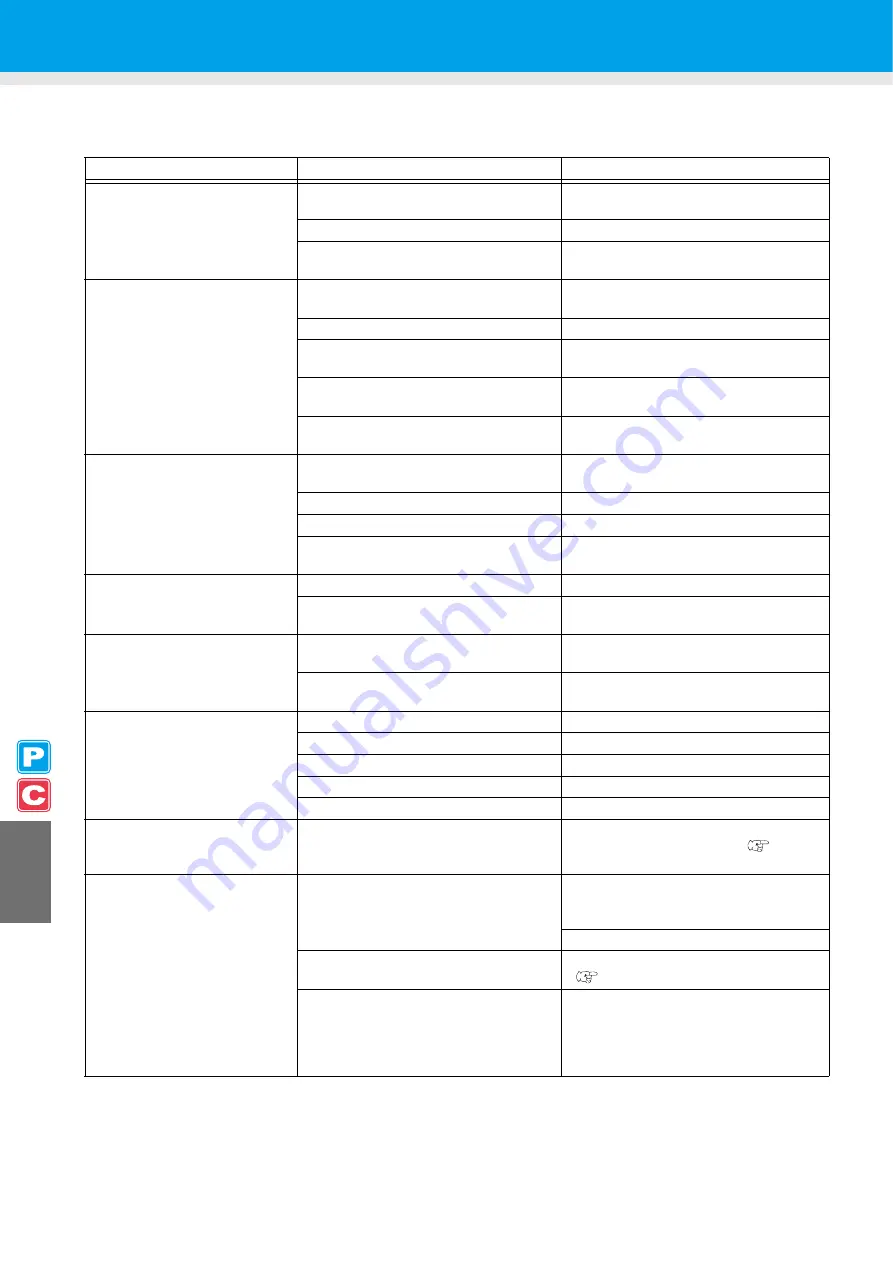

Take the appropriate actions as described below before taking the trouble as a failure. If the problem is still not

solved after troubleshooting, contact your distributor or our service office.

Failure phenomenon

Cause

Solution

Power does not turn ON.

The power cable of the machine is not

connected securely.

Securely connect the power cable of the

machine to the outlet.

The main switch is not ON.

Turn ON the main switch.

The power switch located on the front of

machine is not ON.

Turn ON the power switch on the front of

the machine.

Printing/cutting (printing with a

pen) does not start.

The interface cable is not connected

securely.

Securely connect the interface cable.

The interface cable is not correct.

Use a USB2.0 Hi-Speed-compliant cable.

The message indicating that the ink has

run out is displayed.

Replace the ink cartridge with a new one.

The host computer setting (machine

model, etc.) is wrong.

Check the host computer setting.

The USB driver is not installed.

Install the USB driver included with the

machine.

Medium gets jammed.

Medium is soiled.

A medium other than those

recommended by MIMAKI is used.

Use the recommended medium.

Medium is curled.

Avoid using a medium with curls.

The end of the medium is bent.

Avoid using any medium with bent ends.

The medium is hanging down along the

platen.

Use a take-up device or re-load the

medium on the machine.

[HEAT] or [CONSTANT] LED

does not light up.

The power to the machine is not ON.

Turn ON the power to the machine.

The heater temperature setting is not

effective.

Set the heater temperature higher than

room temperature.

An error occurs in the machine

when the host computer sends

data to the machine.

Command settings are wrong.

Use the application included with the

machine.

Machine model setting is wrong.

Correct the machine model setting to

[CJV30] on the application software.

Cutting produces a perforation

rather than a clean cut.

Screw for the tool holder is loose.

Tighten up the screw.

The cutter blade protrudes excessively.

Adjust the protrusion of the blade properly.

The tool condition is set to [HALF].

Set the tool condition to [CUT1] to [CUT3].

The blade is chipped or worn out.

Replace the blade with a new one.

The blade does not rotate smoothly.

Replace the holder with a new one.

The actual cut length is different

from the length specified on the

data.

The medium feeding length varies with

the medium thickness.

Correct the error margins by executing the

distance correction function. (

Slippage of medium arises in

cutting.

The pinch rollers and grid rollers fail to

securely retain the medium in position.

Check the position of the pinch rollers and

grid roller and adjust them so that they

securely retain the medium in position.

Increase the number of pinch rollers.

The pinch roller pressure is not properly

selected.

Select the proper pinch roller pressure.

(

There is a slack in the roll medium so the

medium fed meanders or skews.

Remove the slack in the roll medium and

straighten the right and left end faces of

the roll when loading the roll medium on

the machine. Then, start feeding the

medium.

Содержание CJV30-100

Страница 15: ...xiv How to Read this Manual...

Страница 16: ...xv...

Страница 158: ...Other Convenient Functions 4 48 12 Press the key...

Страница 239: ...Warning Labels 8 7 8 Appendix No Order No Label 1 M904810 2 M905935 3 M905811 4 M903330 5 M903239 6 M903405...

Страница 243: ...8 11 Function Flowchart 8 Appendix MED I A RES I DUA L PR I NT ENT Only when MEDIA RESIDUAL is ON...

Страница 244: ...8 12 ES 3 I NK MMCCYYKK REMA I N 3 4 5 6 7 8 9 9 HEAD HE I GHT T h i n MMMMMMM 1 0 0 0mm From P8 10...

Страница 261: ...8 29 Function Flowchart 8 Appendix...

Страница 269: ...8 37 Function Flowchart 8 Appendix...

Страница 272: ...8 40...

Страница 273: ...D201873 11 26092008...

Страница 274: ...NH FW 1 1 MIMAKI ENGINEERING CO LTD 2008...