14

19, Item 865) and coupling (860) to allow fre e

rotation of ECC shaft.

5. Ap ply power to ECC and allow it to run to it s

new position at a zero mA signal. Ensure t he

capacity control knob did not rotate.

6. Ap ply a 4 mA signal to place ECC in reverse-

acting mo de. This is now the 1 00% capacity

setting.

7. With ECC and pump capacity knob at 10 0%

capacity setting, carefully slide the ECC shaft

back into th e co upling a nd re place th e fo ur

mounting screws. If req uired, rotate the pump

adjustment sc rew to allow ass embly. Do not

move the ECC shaf t. On MaxRoy B pumps

tighten coupling nut (Figure 19, Item 865) and

coupling ( 860) (Approximately 4 0 lb . ft.). Pin

should remain in approximate mid point of slot

in coupling.

8. Che ck operation through full signa l range and

recalibrate if required (See ECC Calibration,

Section 4).

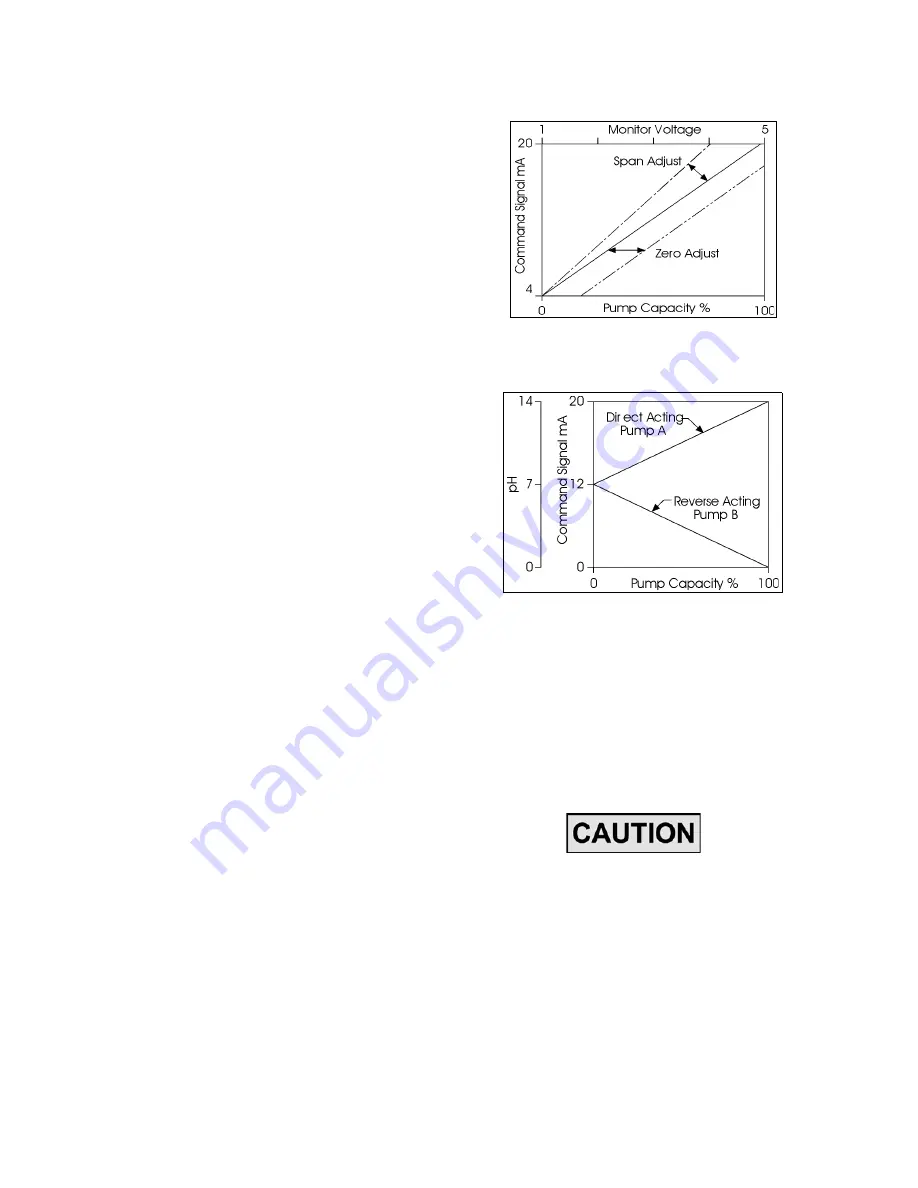

3.2.2 Input Signal

The ECC is sh ipped from the factor y a djusted to

accept a 4-20 mA command signal. If the unit is to

be operated with any other range, it must be set up

for that range.

•

Adjusting the span control, VR1, Figure 11,

determines th e m aximum tr avel o f t he

ECC over the full r ange o f the com mand

signal.

•

Adjusting the zero control, VR2, Fig ure 11

shifts the position of this travel (Figure 9).

The ECC ma y b e set up to op erate over a “split

range” of either 0 to 100% capacity corresponding

to a 12 to 20 mA signal, or 0 to 100% capacity cor-

responding to a 1 2 to 4 mA sign al ( in r everse

action mode) - such as pumps A & B in a typical pH

control system, shown in Figure 10.

Figure 9. Effect of Zero & Span Controls.

Figure 10. Split Range Operation w/Two Pumps

(Typical pH Control System).

3.3 CONTROL RANGE ADJUSTMENT

First remove the cover from the ECC. On the ECC-

circuit bo ard, Figu re 1 1, a re four lig hts an d four

small tr im pote ntiometers. The light s are in pairs.

The pots are for zero, span, upper limit, and lower

limit adjust.

THE LIMIT POT ENTIOMETERS MUST

BE SET BEFORE CHANGING THE CON-

TROL RANGE. THEY MUST

BE

ADJUSTED (AS THEY ARE AT THE

FACTORY) TO PREVENT OVERTRAVEL

OF THE CONTROL SPOOL. IMPROPER

ADJUSTMENT OF THESE UPPER AND

LOWER LIMIT TRIM POT

S MAY

RESULT IN DAMAGE TO THE PUMP OR

THE ECC.

www.motralec.com / [email protected] / 01.39.97.65.10

Содержание MacRoy

Страница 19: ...11 Figure 7 Conversion Detail www motralec com service commercial motralec com 01 39 97 65 10...

Страница 20: ...12 THIS PAGE INTRNTIONALLY BLANK www motralec com service commercial motralec com 01 39 97 65 10...

Страница 24: ...16 Figure 12 Circuit Board Bottom www motralec com service commercial motralec com 01 39 97 65 10...

Страница 38: ...30 THIS PAGE INTENTIONALLY BLANK www motralec com service commercial motralec com 01 39 97 65 10...

Страница 54: ...46 THIS PAGE INTENTIONALLY BLANK www motralec com service commercial motralec com 01 39 97 65 10...

Страница 61: ...53 THIS PAGE INTENTIONALLY BLANK www motralec com service commercial motralec com 01 39 97 65 10...

Страница 63: ...55 THIS PAGE INTENTIONALLY BLANK www motralec com service commercial motralec com 01 39 97 65 10...