Flooded type water cooled screw chiller (PCB Control)

88

9) Before start up the machine, inspect whether the external system of the unit meets the conditions for

start-up (e.g. whether the water cooling pump of the system is externally controlled or interlocked with

the master compressor, and that the water pump must be started before starting up the master

compressor via external control).

10) Inspect whether the compressor overload protection value, which shall not exceed the maximum

compressor permissible current value indicated in the nameplate on the compressor, is set correctly. The

compressor overload protection value generally equals to the set value of heat relay multiplied by

variable ratio of current inductor, which is (250/5)50 in the following case.

11) Inspect whether the value of phase loss and reversal protection is set correctly. The

over-/under-voltage protection value shall be ±10% of the rated voltage.

(2) Refrigeration System Inspection

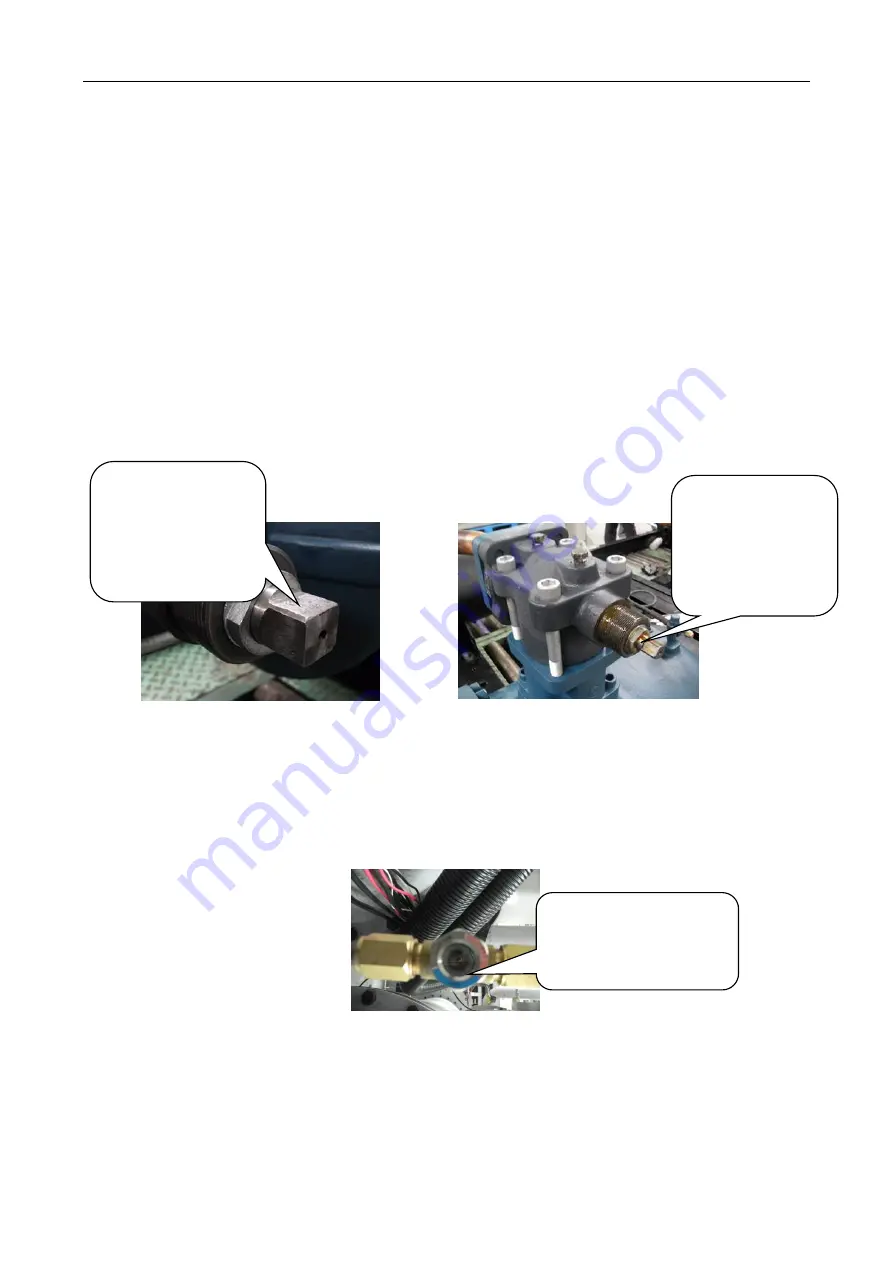

1) The discharge line valve and suction line valve of the compressor must be fully open (turn

anticlockwise to open) and the cores shall be tightly locked to prevent leakage of refrigerant.

2) Inspect whether moisture content of the system exceeds the limit

Excessive moisture content in the refrigerant system of the unit might cause ice block, copper plating, etc. that

would seriously affect the safety of the unit. Therefore, the dryness of the refrigerant system of the unit shall be

inspected from the sight glass before and during operation of the unit, purple indicating dry, and pink moist, as

shown in the right figure. When the color turns red, the filter core in the unit shall be replaced with a dry one.

3) Sufficient lubricating oil in the oil tank (not lower than 1/2 of the oil level in the high oil immersion

lens), and no deterioration (blackness).

Inspect the oil level and quality before start-up for the two factors have direct impact on the

performance and reliability of the unit. There must be sufficient lubricating oil in the unit. And during the

shutdown of the unit, the high oil immersion lens must be full of oil.

The discharge line

valve and suction line

valve shall be open

(both valves in the

figure are closed, and

shall

be

opened

before start-up).

The

discharge

line

valve and suction line

valve shall be open

(both valves in the

figure are closed, and

shall be opened before

start-up).

The color is indicated in the

center and compared with

the color card around it to

reflect the moistness in the

system.