7

Software Set Up (continued)

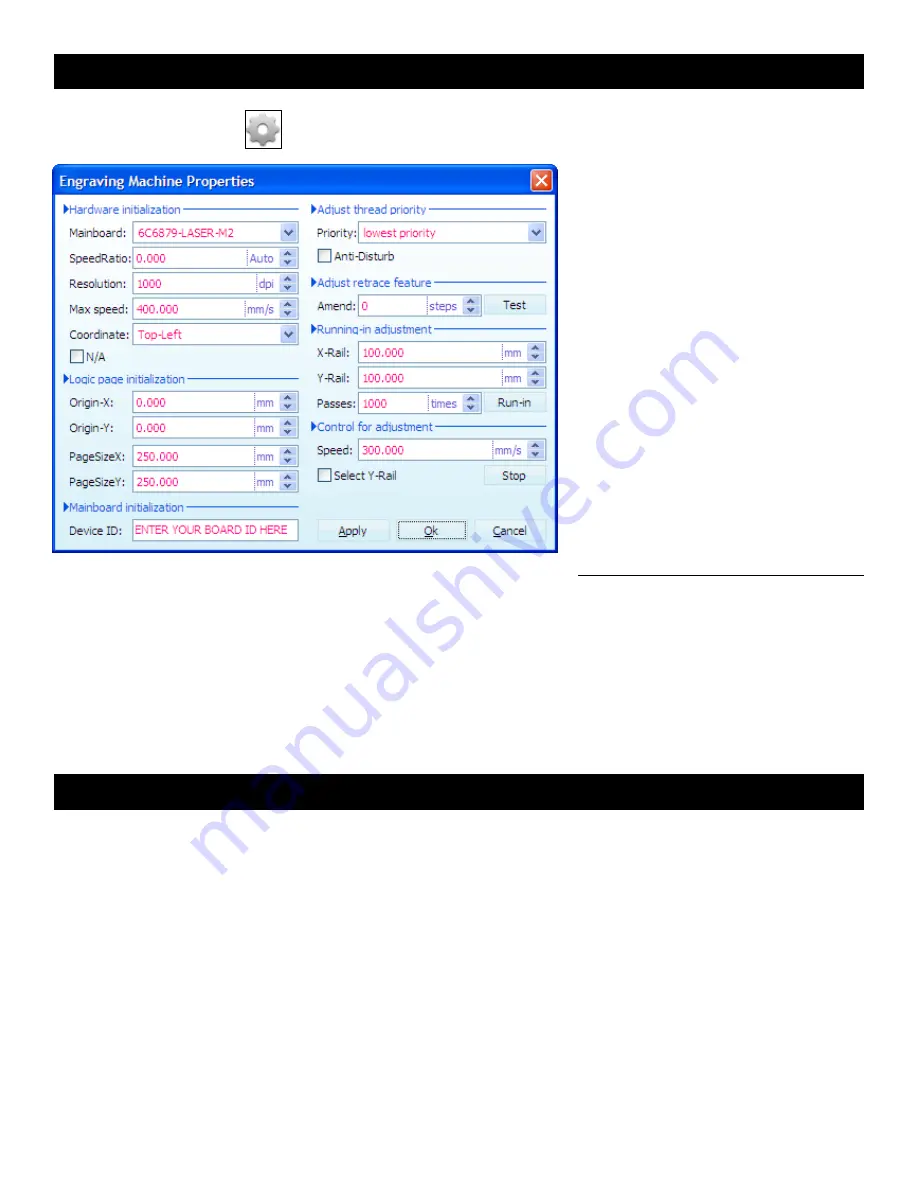

Next, click on the gear icon (third to the right of the green pencil you clicked on before). You should see a window

that looks like the following:

Check the settings, and use the pull-down

menus to change them to what’s shown at

left.

Notice the field in the lower left corner

…“Device ID.”

IMPORTANT:You’ll need to

enter your specific machine

identification number in this

field.

This number can be found on a label

located above the opening in the machine

cabinet through which you plugged in the

USB cable. If you do not enter or replace

any existing number with the correct ID, the

machine will not respond to the computer

commands. For future reference, take a

moment now to write the machine ID

number on the following line:

WARNING! You must be certain that the PageSizeX and PageSizeY are set to a

maximum of 250.000 mm as shown above.

A higher setting will cause the machine to run the carriage into the end stops and may damage the machine. A lower setting

will do no harm, other than restrict the overall size of the image you will cut or engrave.

Be sure to click OK to accept and save your settings. If so instructed, “X-out” and then restart the CorelLASER application to

activate the new device ID and initialize installation of the software.

OK, now it’s time to open a drawing file and cut out some parts. We’ve included a couple of simple sample files to get you

started.

In the upper left corner of the CorelDRAW window, click on File, then Open. Navigate to LaserKnife demonstration files,

double-click and select Laser Cut HO shanty Demo by double-clicking the file name. A set of wall outlines should appear.

(Notice that additional CorelDRAW functions also appear). Click on an object line, hold the mouse key down, and drag

the image to a location near the top of the page. Release the mouse button. If the object stays selected (black squares

appear around the outline), don’t touch it. If it is not selected, click on an image line to do so. Because of previous settings to

cut “only selected,” you need to select the image, which we’ve grouped together for you, for the machine to accept for cutting.

Tip: You can also “select all>objects” under Edit.

Turn ON the LaserKnife Master ON-OFF switch and verify that the water is flowing by lifting the return water line out of

the water in the bucket and visually checking for flow. If water is flowing, place the return tube back under the water. If no

water is flowing, correct the problem before continuing.

You may also turn on the chamber light using the lighting switch on the control panel.

Let’s Try Cutting Out Some Parts

ID: