7 ND90 71 en

21

4.5.1 Remote mounting

ND9100H,ND9100F, ND9100P, ND7100H

For applications if there is e.g. heavy vibrations, environ-

ment temperature is very high or access is difficult, there is

available remote position measurement option. In this kind

of applications position sensor is attached to actuator and

ND9000 can be installed further away. Pneumatic piping

between ND9000 and actuator is done as explained in

chapter 4.6 and wiring between position sensor and

ND9000 according to Fig. 13.

There are three different cable lengths available between

ND9000 and remote position sensor: 1.2m, 3m and 30m.

If position sensor is remote mounted to linear actuator,

there are some parameters which have to be defined as fol-

lowing:

valve acting type (VTYP) have to be defined as rotary

valve rotation direction (ROT) have to be defined as

Clockwise to Close (CC)

Remote position sensor for rotary actuators is available also

with limit switch.

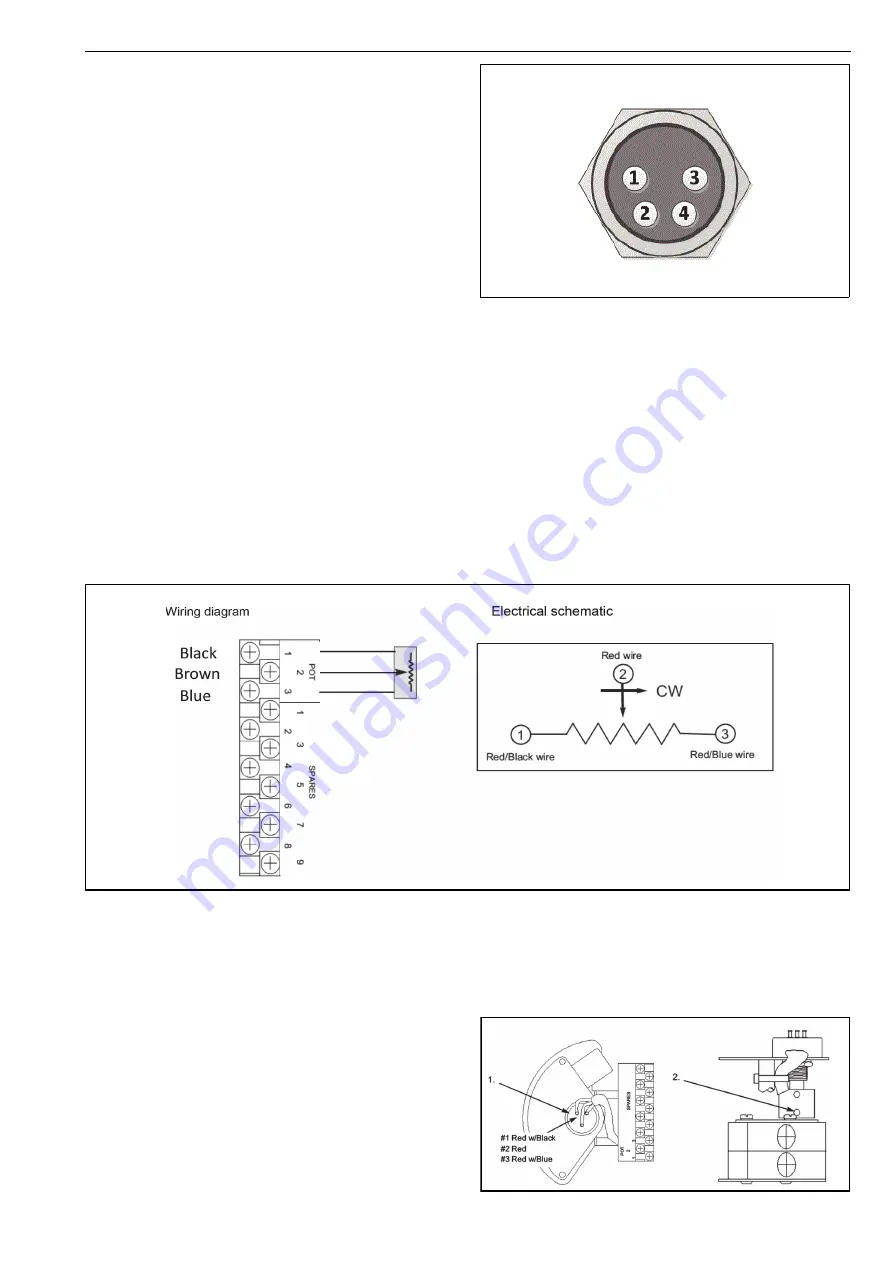

Fig. 14

Pin assignment in female connector view (connec-

tor in device)

Pin assignement

Pin# Function

1

Cable Shield Ground (Ground)

2

Potentiometer Plus (Blue)

3

Potentiometer Center (Brown)

4 Potentiometer

Minus

(Black)

4.5.2 Quartz position sensor connections and calibration

Potentiometer Calibration

1.

Operate the actuator to the desired “zero” position.

Connect an ohm meter across the terminals POT 1 &

POT 2 to measure the potentiometer output.

2.

Loosen the bottom set screw and rotate the coupling

until the ohm meter reads approximately 5k Ohms

(assuming a 10K Ohm potentiometer). Retighten the

set screw and verify the ohm meter still reads

approximately 5k Ohms.

3.

Operate the actuator to the desired “100 %” position

(assuming 90 degree rotation) and verify the ohm

meter reads (2.7K Ohms or 7.7K Ohms +/- 10 %,

depending on rotation direction).

4.

Remove all test equipment.

5.

Connect the position sensor cable to the terminal

strip as shown in the above wiring diagram.

6.

Connect the connector end of the position sensor

cable to the ND9000 female connector shown in

Fig. 13.