4

3

2

1

4.1

EN

18

17. Service and maintenance

1

Safety valve check

Check if the safety valve functions properly during first use of the

compressor.

Pull the ring at the top of the safety valve to check if air is vented

properly.

Safety valve must not be used to relieve air from the air

receiver! Always protect eyes from compressed air using

safety glasses!

2

Air line filter and dryer prefilter cartridge replacement

Prefilter and dryer prefilter cartridges (0,5 µm and 0,01 µm) must be re

-

placed every year.

Disconnect the compressor from the main supply

Open the air drain cock or the condensate relief from the air receiver

and relief residual pressure contained in the air receiver

Manually unscrew the filter receiver

Unscrew the cartridge as shown in the picture above and replace it with

the new cartridge

Fix again the filter receiver

i

Carefully place the o-ring on the lip of the filter receiver.

Replace the o-ring as necessary.

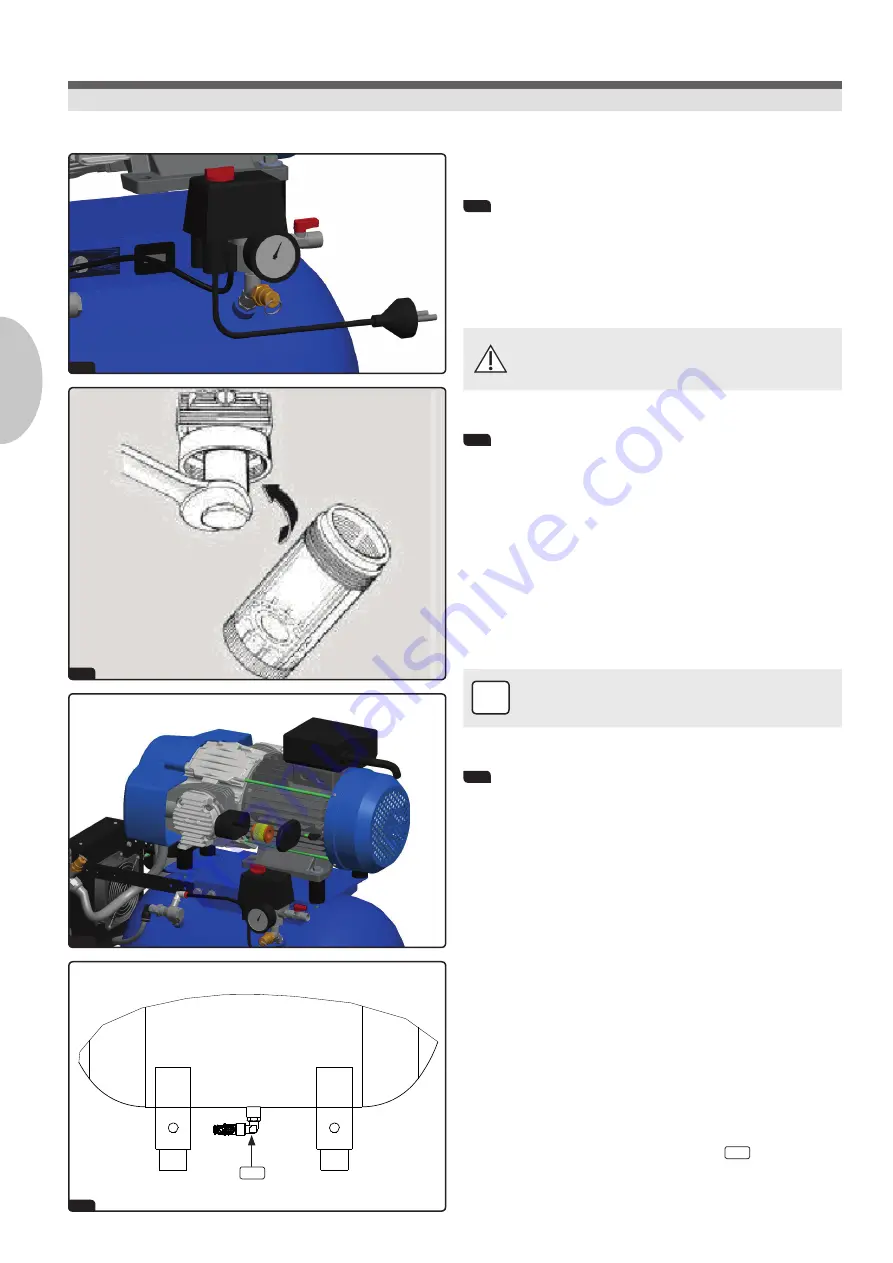

3

Replacement and cleaning of the air intake filter

Clean the air intake filters every year with compressed air or water, or re

-

place if necessary.

18. Decommissioning and disposal

Decommissioning

If the compressor is not to be used for a longer period of time, it is re-

commended to drain the condensate from the pressure tank. Then the

compressor must be operated for approx. 10 minutes with the condensate

drainage tap open. Afterwards, switch off the compressor at the pressure

switch, close the condensate drainage tap and remove the mains plug.

Disposal

After disconnecting the appliance from the mains electricity supply by

removing the mains plug, the air pressure in the pressure tank must be

released by opening the condensate drainage tap

4.1

.

When disposing of the compressor, all necessary safety precautions must

be taken in order to avoid harm to persons or objects.

Service and maintenance

Decommissioning and disposal

Practice personnel, technicians