25

OPERATION MANUAL

6.3 TOP SLIDE ADJUSTMENT

The top slide clearance tolerance has been set in the

factory but may at some time need to be adjusted.

The clearance should be between 0.06 ~ 0.10 mm. If the

clearance is not in the tolerance range, then the clearance

must be adjusted by the following steps below

To adjust the top slide.

1. DISCONNECT THE MACHINE FROM THE POWER SUPPLY

2. The two slides adjustment bolts can be found at the

back of the machine. (Fig.6.4)

3. Using a feeler gauge between the slide and the keeper

plate, check the clearance. If the clearance is not

between 0.06 ~ 0.10 mm then adjustment is required.

(Fig.6.5)

4. To adjust, loosen the two lock nuts on one side (Fig. 6.6)

and adjust the bolts until the clearance is within the

tolerance.

5. Tighten the two lock nuts and repeat the process on

the other side of the machine.

6. Once completed, check the clearance again.

7. Once the slide clearance has been set then the “Setting

The Blade Gap” (Page 22) process needs to be checked.

F

ig

. 6.4

F

ig

. 6.6

F

ig

. 6.5

L

ock

nuts

Before doing any adjust-

ment to the machine, disconnect the machine from the

power supply and place a sign on the front of the machine

warning any operator that the machine is being worked on

and must not be used until all adjustments have been made

and personnel are clear of the back of the machine.

Failure to comply may cause death or serious injury.

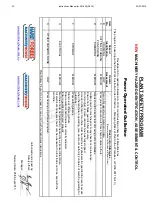

22/07/2019

Instructions Manual for SG-420 (S535)

25