QC11Y Hydraulic Guillotine Shear

17

8、

Maintenance &Trouble Shooting

8.1 Blades

8.1.1 The blade clearance (blade gap) adjustment:

It is a very important factor to adjust the blade clearance which relates the cutting quality and knife life. Pls follow below procedures: the clearance data is 0.07~0.1 times of the plate thickness, the plate thickness =0.07~0.1t. The above is for Ob=450-500N/mm

2

.

For more

than450-500N/mm

2

, it is suggested to use smaller clearance. And for less than 450-500N/mm2, pls use larger clearance. Turn the handwheel in the front of the plane board to adjust the clearance data. That means adjust the clearance according to the plate thickness. The data will

be displayed on the handwheel

8.1.2 measuring of blade clearance and adjustment of the proportional clearance

the proportional clearance relates the cutting quality directly. It is set up by the manufacturing and unnecessary to modify normally. After the machine has been used for a period of time and if the knife side is changed, then it is a must to adjust the blade clearance again . The

adjustment procedure is as below: turn the switch to adjust mode, adjust knife beam to balance( cutting angle is 0, Turn the clearance adjust hand wheel anticlockwise to the “smallest clearance”, turn off main motor(power on), press oil filling button, move knife beam down until

distance between upper and bottom blades is 3~5mm, adjust the bolts and nut which support bottom blade on work table, use the plug gauge to inspect the clearance. After the adjustment is finished, repeat reset course of knife beam(5.2.C).

8.1.3 The installation of the blade

After the machine has been used for a period of time, must turn over the blade sides

or change the blade. The installation of the upper blade is as below: make the upper

knife beam flat( the cutting angle is 0 ). Then turn off the screw at the lower knife to

change the blade or turn over the blade. (be careful of the sharp blade to avoid hurt.)

it is easier to change the lower blade.Just take off the upper blade cover at the

working table and turn off the screw to change the blade or turn over the blade.

8.1.4

The grinding and change of the blades

Содержание HG3208VR

Страница 1: ...19 3 08 HG3208VR HYDRAULIC GUILLOTINE MANUAL S960...

Страница 2: ...QC11Y 8X3200 Hydraulic Guillotine shears Operation Manual Serial No Q709103...

Страница 3: ...QC11Y Hydraulic Guillotine Shear 1 Contents...

Страница 4: ...QC11Y Hydraulic Guillotine Shear 2...

Страница 6: ...QC11Y Hydraulic Guillotine Shear 4...

Страница 8: ...QC11Y Hydraulic Guillotine Shear 6 4 Hoisting and Installation...

Страница 13: ...QC11Y Hydraulic Guillotine Shear 11 overflow valve 5...

Страница 14: ...QC11Y Hydraulic Guillotine Shear 12...

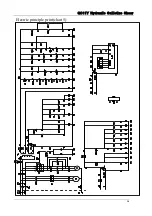

Страница 16: ...QC11Y Hydraulic Guillotine Shear 14 Electric principle print chart 5...