Содержание HG3208VR

Страница 1: ...19 3 08 HG3208VR HYDRAULIC GUILLOTINE MANUAL S960...

Страница 2: ...QC11Y 8X3200 Hydraulic Guillotine shears Operation Manual Serial No Q709103...

Страница 3: ...QC11Y Hydraulic Guillotine Shear 1 Contents...

Страница 4: ...QC11Y Hydraulic Guillotine Shear 2...

Страница 6: ...QC11Y Hydraulic Guillotine Shear 4...

Страница 8: ...QC11Y Hydraulic Guillotine Shear 6 4 Hoisting and Installation...

Страница 13: ...QC11Y Hydraulic Guillotine Shear 11 overflow valve 5...

Страница 14: ...QC11Y Hydraulic Guillotine Shear 12...

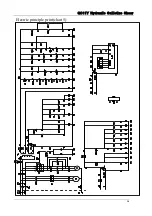

Страница 16: ...QC11Y Hydraulic Guillotine Shear 14 Electric principle print chart 5...