15

LUBRICATION & MAINTENANCE

X

Check all hardware for tightness

X

Check all belts for proper alignment

X

Check engine oil level

See engine operator's manual

X

*Clean air cleaner element

See engine operator's manual

X

Check operator presence system

See page 5

X

Check tire pressure

See page 8

X

Check belt tension

See page 9

X

Sharpen cutter blades

See page 11

X

Check hydraulic oil level

See page 16

X

*Clean mower

See page 17

X

Change engine oil and filter

See engine operators manual

X

Grease spindle bearings

+ US Lithium MP White Grease 2125

X

Check hydraulic oil level

See page 16

X

Change engine oil

See engine operator's manual

X

Check all belts for proper alignment

X

*Replace air filter element

See engine operator's manual

X

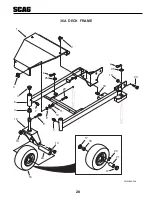

Grease caster wheel bearings

Chassis grease

X

Check all hardware for proper tightness

More often if needed

X

Grease brake hand lever

Chassis grease

X

Grease brake actuator levers

Chassis grease

X Drain hydraulic system and replace oil & filter

See page 16

X Grease caster wheel pivot shafts

** Chassis grease, see instructions below

X Replace engine fuel filter

See engine operator's manual;

X Adjust air gap on electric clutch

Contact your Scag dealer for information about

this maintenance procedure.

BREAK-IN

8 HOURS (DAILY)

20 HOURS

40 HOURS (WEEKLY)

100 HOURS (BIWEEKLY)

500 HOURS OR ANNUALLY

COMMENTS

PROCEDURE

+ Grease spindle until grease comes out the relief valve.

Compatible Greases:

Lidok EP #2 (found at industrial shops)

Ronex MP (Exxon service stations)

Shell Alvania (Shell service stations)

Mobilux #2 (Mobil service stations)

Super Lub M EP #2 (Conoco service stations)

* Perform these maintenance procedures more frequently under extreme dusty or dirty conditions.

** PROCEDURE: Remove grease cap, part number 481559. Remove plug, part number 482028-01, and install

standard grease zerk (p/n 48114-06). Apply grease to the fitting until new grease appears at the top of the

caster extension. Remove the grease zerk and reinstall the plug. Reinstall the grease cap. Special tool, part

number 47007, is recommended for use in the installation of the grease cap.

Содержание SCAG POWER EQUIPMENT SWZU Series

Страница 27: ...23 NOTES...

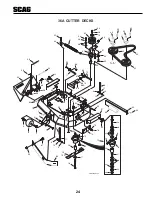

Страница 32: ...28 36A DECK FRAME 1 2 3 4 5 4 7 7 8 9 10 11 12 13 14 15 23 19 16 22 SWZU06DF36 24 25 6 25 6 17 18 20 21 17...

Страница 47: ...43 WIRE HARNESS ADAPTER PART NO 481717 KAWASAKI 16 HP 17 HP 19HP SWZU06WH481717...

Страница 49: ...45 REPLACEMENT DECALS AND INFORMATION PLATES 11 482297 13 FAST SLOW PARKING BRAKE OFF ON 10 12 SWZU 481906 9...

Страница 51: ...47 NOTES...

Страница 54: ...2 3 NOTAS...