28

2. Metal Loss

The metal loss value is available both through the “MEASURE PROBE” and “VIEW STORED DATA”

functions, and is shown as MILS (1 MIL = 0.001 inches). The instrument automatically performs the

calculation shown in equation 1, p. 27, and displays the result on the MS3500E/3510E screen.

The metal loss value shown is the total metal loss since the probe was new. Consequently, this

value is only valid when the probe used is initially installed as new. If a partially consumed probe

is attached to an MS3500E/3510E to perform a logging sequence, the MILS value shown will be an

overestimation of metal loss at the present locations by an amount equivalent to the thickness loss prior

to the commencement of logging operations.

3. Corrosion Rate

This value is also available through the “MEASURE PROBE” and “VIEW STORED DATA” functions

and is expressed as MPY (1 MPY = 0.001 inches per year). This value is calculated on the basis of

equation 2, p.27.

Again, the calculation is an average corrosion rate assuming an as new condition for the probe

element at the beginning of the logging sequence.

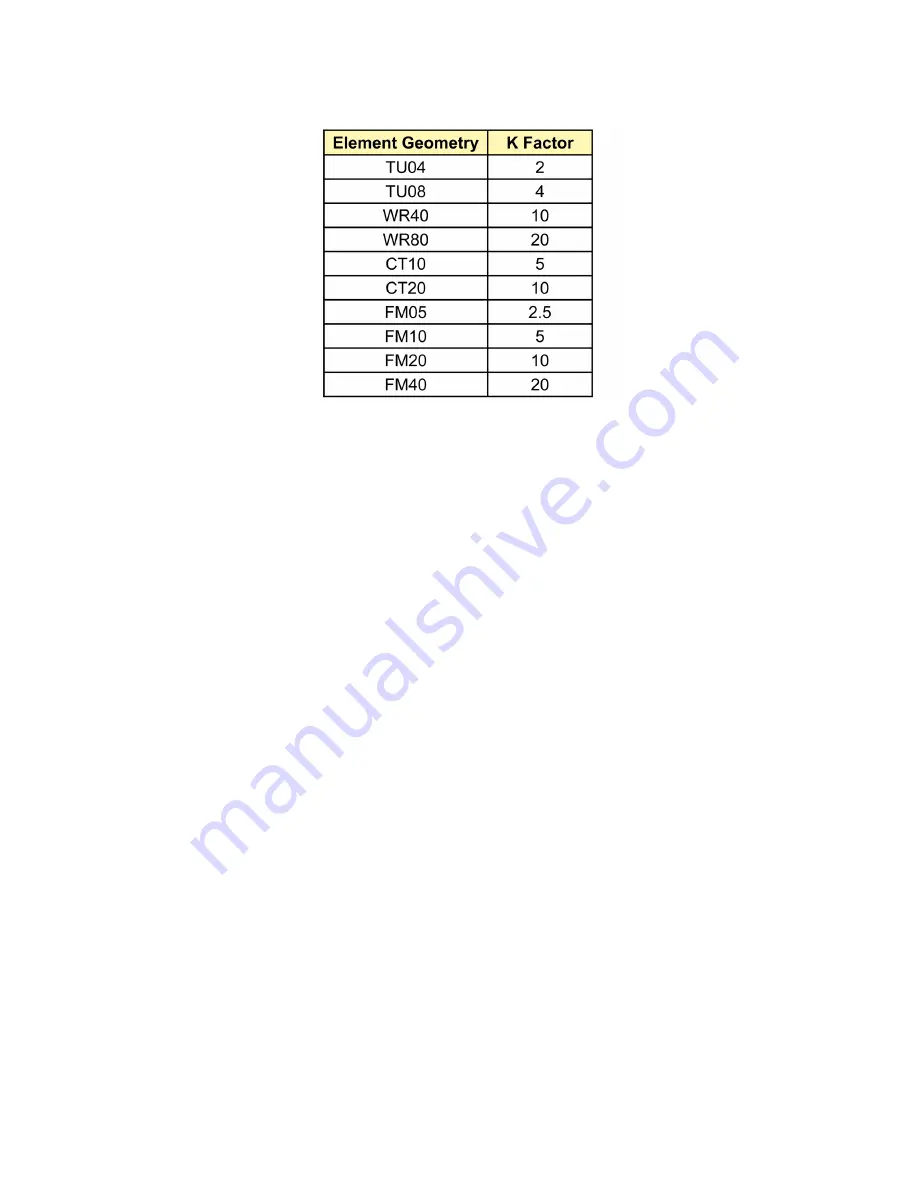

Table 1. Probe Constant

Содержание MS3500E

Страница 2: ... ...

Страница 40: ...36 Figure 8 Element Selection Guide Element Life ...

Страница 41: ...37 Figure 9 Element selection guide response time ...