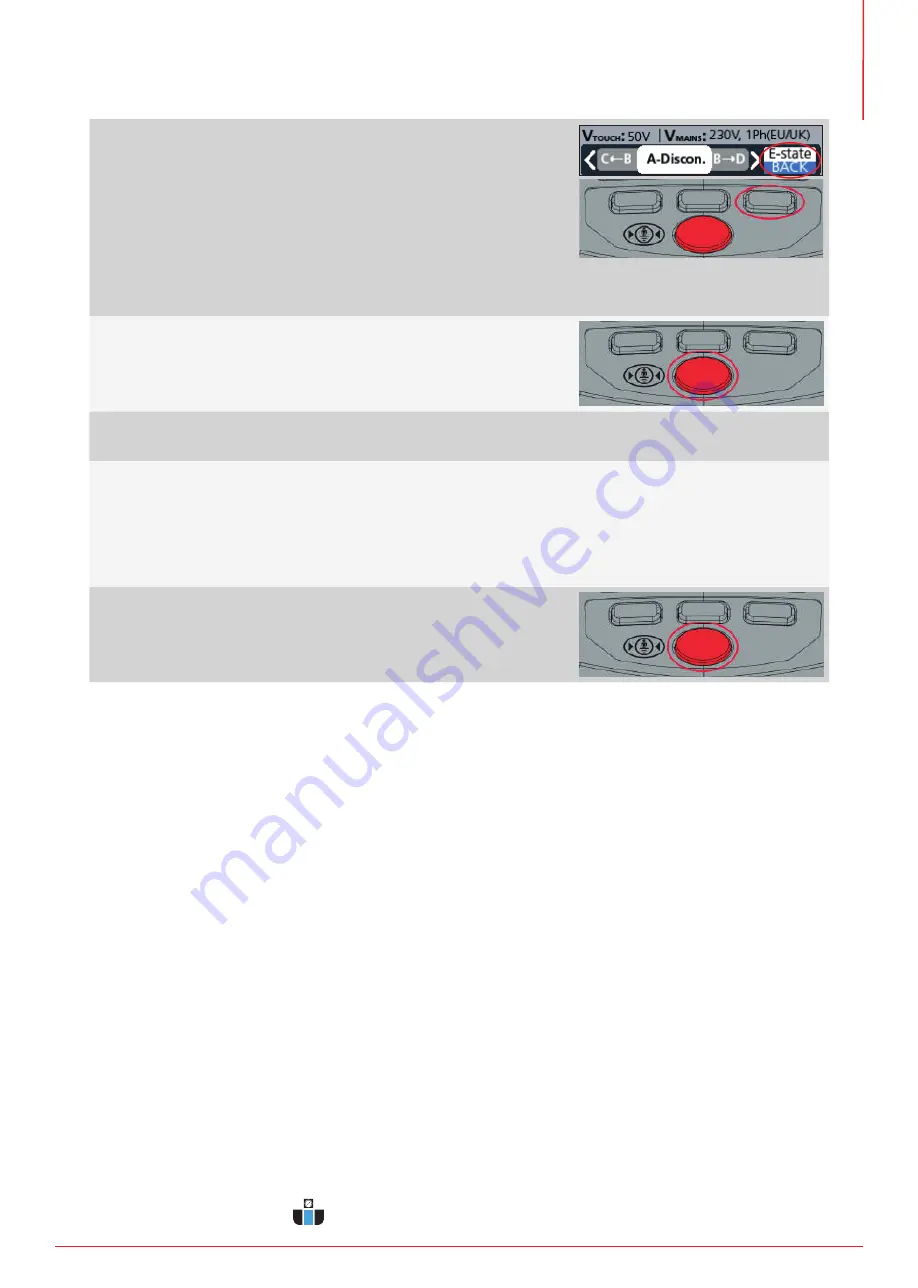

8. Press softkey 3 to set a CP short to E to test the chargers

response.

At this point no measurements are taken, only the CP code

applied to the charger.

9. Press and hold softkey 3 to use the BACK function that will

exit the EVSE interface screen

10. Long press the TEST button to start the test and take

measurements.

11. The test will take a few seconds to perform and measure all of the required parameters.

12. When complete the EVCC300 will also indicate the CP state measured back from the charger along the

bottom of the white part of the display.

Note

: each press of the TEST button will take one set of measurements. The test results are not a continuous

measurement.

13. Re-pressing the TEST key will repeat the test measurements

Repeating the measurements will assist in looking for stability in

voltages etc.

5.7.3 Interpreting test results

Generally the user should check that all of the measured parameters are as expected. The EVCC300 performs a single

measurement of each parameter every time the test button is pressed.

1. The output charging voltages and frequency should be as expected for the type of supply the charger is

connected to.

2. The polarity of the charger should read OK. If the polarity is incorrect the result will be INV.

3. The IMAX read by the EVCC300 should match what the rating of the charger is or the rating of the connecting

cable used.

NOTE:

when EVCC300 is plugged directly into a charger the PP resistance applied sets the lead rating to 32A.

4. The control pilot voltage, duty cycle and frequency measurements should be repeatable when the test

is repeated.

5. The CP state read from the charger by the EVCC300 should match the code set for the test. Should the code

measured be different from that set the charger indicates it is faulty.

6. Should the read back control pilot indicate a code “F – Fault” it means that there is a fault or error with the

charger itself.

33

Tests

www.calcert.com

1.800.544.2843

0

5

10

15

20

25

30