A/C System

Basic Climate Control

Condenser

•

The condenser receives heated refrigerant from the compressor and reduces the

temperature, thereby liquifying it. Refrigerant normally boils at –26°C, but under pressure

the boiling point is increased, so accordingly the condensation point is increased. This

means that as the relatively cool outside air passes the condenser, it absorbs the heat

from the refrigerant, allowing it to change state. As a result, the air passing by the fins of

the condenser increases in temperature as it absorbs the heat from the refrigerant.

•

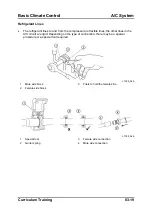

The condensation process is plotted on the graph below. Point 2 represents the stage in

the A/C system after the refrigerant has left the compressor and before it enters the

condenser. At this point the refrigerant is a high pressure, high temperature gas.

Between 2 and 3 is the condensation process. Notice that the path crosses below the

liquid / gas curve; meaning at point 3 the refrigerant is in a liquid state. It should also be

noted that during condensation the pressure does not change.

Condensation Plotted on the Refrigerant Curve

L1005_023b

X Pressure

Y Temperature

1-2 Compression

4-1 Vaporisation

2-3

Condensation

5

Refrigerant liquid / gas curve

3-4

Expansion

(above is gaseous, below is liquid)

•

The three different types of condensers are explained on the following pages. The

condensers are all mounted forward of the radiator.

03-8 Curriculum

Training

Содержание CT-L1005

Страница 1: ...Training Manual Basic Climate Control CT L1005...

Страница 20: ...Fundamentals Basic Climate Control Notes 02 14 Curriculum Training...

Страница 52: ...A C System Basic Climate Control Notes 03 32 Curriculum Training...

Страница 66: ...List of Abbreviations Basic Climate Control Notes 06 2 Curriculum Training...