Installation and Operational Instructions for

ROBA-stop

®

-S brake Type 856. _ _ _ . _

Size 11

(B.8.3.1.GB)

19/11/2010 TK/KE/GC/SU

Chr. Mayr GmbH + Co. KG

Tel.: 08341 / 804-0

Eichenstraße 1

Fax: 08341 / 804-421

D-87665 Mauerstetten

http://www.mayr.de

Page 12 of 13

Germany

E-Mail:

Braking Torque Adjustment (Figs. 1 to 3)

The ROBA-stop-S brake Size 11 is set manufacturer-side to the

nominal torque or to the braking torque stipulated on order.

Braking torque adjustment is carried out by evenly removing or

adding thrust springs (6 and 29) to the internal or external pole of

the coil carrier (2) acc. Table 1.

DANGER

By removing the brake plate (16), the braking

torque is nullified. Load movement must be

prevented.

Procedural Method:

1. Remove the brake plate (16) by loosening the hexagon

head screws (17). Please observe the adjusting plates (28).

If necessary, use the emergency release screws (9) as a

removal aid. In this case, the screw plugs (10) with the

copper sealing rings (11) must be unscrewed and screwed

in again after brake plate (16) removal.

2. Remove the rotor (4).

3. Evenly loosen the 3 cap screws (7), which together with the

collar bushings (8) hold (guide) the armature disk (5) axially,

until the armature disk (5) can be removed.

Danger! The armature disk is subject to spring pre-

tension!

4. Remove abraded particles from the rotor and clean the

brake.

Do not use grease or oil!

5. Adjust the required braking torque by evenly removing or

adding thrust springs (6 and 29) to/from the coil carrier (2)

(see Table 1).

One spring (6) at the internal pole equals

102 Nm.

One spring (29) at the external pole equals

61 Nm.

The thrust springs (6) at the internal pole of the

coil carrier and the thrust springs (29) at the

external pole of the coil carrier must not be

interchanged (see Table 1).

6. Insert the armature disk (5).

Please make sure that the two pins for actuating the

microswitch situated next to each other protrude into

the terminal box.

7. Screw the armature disk (5) back on using cap screws (7)

and added collar bushings (8).

Observe the tightening torque of 85 Nm!

8. Push the rotor (4) back on. Check that the toothing moves

easily.

The rotor (4) must be placed onto the hub (1)

so that the toothing remains engaged even after

wear on the friction linings.

9. Mount the brake plate (16) again using hexagon head

screws (17). Please make sure that the emergency release

has the correct angular position (see Fig. 2).

Do not damage the O-rings (18 and 19)!

Observe the tightening torque of 46 Nm!

Table 2: Spring Configuration

Number of springs Ø 22 / 4,5 x 50

at internal pole (Item 6)

Torque on

brakes

[Nm]

2

3

4

5

2

326

428

530

632

3

387

489

591

693

4

448

550

652

754

N

u

m

b

e

r

o

f

s

p

ri

n

g

s

Ø

1

9

/

3

,6

x

3

8

a

t

e

x

te

rn

a

l

p

o

le

(

It

e

m

2

9

)

5

509

611

713

815

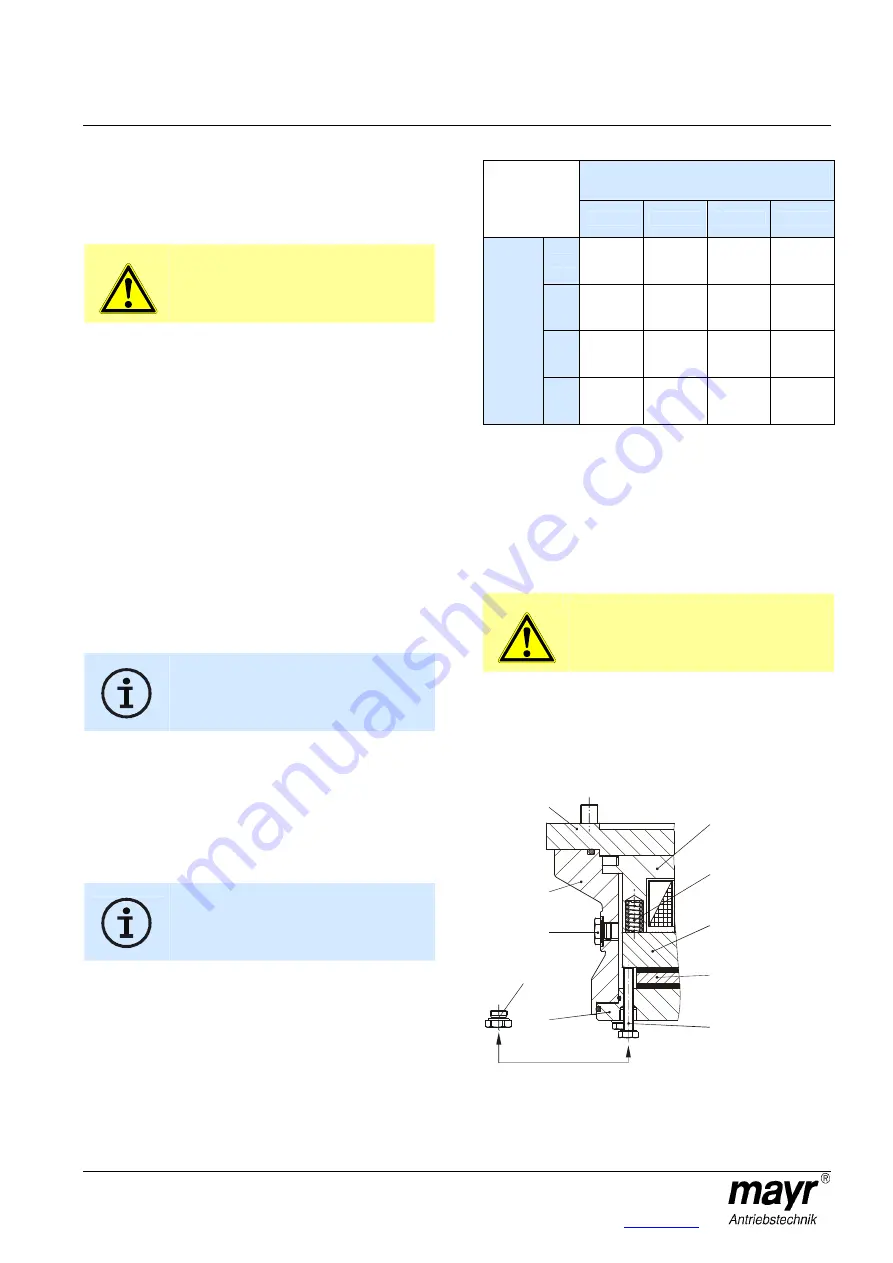

Emergency Release (Fig. 13)

In case of malfunction or power failure, the brake remains

closed; it cannot be released electrically. Emergency release can

be carried out manually.

1. Unscrew the screw plugs (10) inc. the copper sealing rings

(11).

2. Screw in both emergency release screws (9) evenly until the

load on the motor starts moving.

DANGER

Caution with hoist drives!

Actuating the emergency release nullifies the

braking torque.

Load crashes must be prevented.

Interrupt the release procedure with individual stops (turning

back the emergency release screws), so that there is no

high load acceleration and brake heating occurrence.

3. After completing the emergency release procedure, unscrew

both emergency release screws (9) again.

4. Screw the screw plugs (10) inc. the copper sealing rings

(11) back in.

Fig. 13

29

4

9

5

2

3

16

31

12/13

10/11