6.0 TENSION CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 18 of 68

6.3 LOAD CELL CALIBRATION (REQUIRED)

Navigate to the

Cal Sensors

menu. Press

.

Select

YES

to calibrate sensors. Press

.

Unload the sensing roll. Remove all web and weight from the sensing roller before

pressing

.

Pressing

will overwrite previous calibrations.

When

Maximum Tension

appears, press

to enter the maximum tension that will

be used on this system (if different than that displayed. This is the upper limit of the

tension range as read by the load cells. Choose a value for the Max Tension that

will have room for the highest setpoint tension you plan to run, plus any tension

errors that may occur during operation within the limits of the load cell load rating.

This setting also scales the analog bar graph. (Usually it is best to set

Maximum

Tension

to approximately twice the value of the normal running tension.) When

finished press

.

Enter the

Applied Tension

you will use to calibrate the load cells.

Press

.

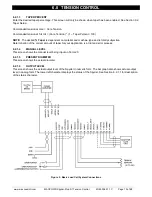

Apply the tension to the sensing roll. This tension should be applied to the sensing

roll using a rope or narrow web that is routed around the sensing roll in the same

way as the normal web. See Figure 7. This tension is best applied using a weight,

but a spring scale can also be used. Press

.

Calibration has been performed. Remove the calibration load from the sensing roll.

Figure 7. Applied Calibration Tension

6.4 TUNING (REQUIRED)

Two steps are involved.

1)

Quick Stab

to get the control loop stable if upon start-up the default

parameters do not provide a stable closed loop. See Section 6.4.1.

2)

Tuning

optimizes the Spyder by first tuning to make the system slightly

unstable; then adjusting the tuning parameters to make it stable. By doing so

the system is tuned to be as responsive as possible and still remain stable

throughout its range of operation. See Section 6.4.2.

Содержание MAGPOWR Spyder-Plus-S1

Страница 2: ......