Mas Grup

4

Damages caused in transport

Check the pump when it is delivered to you. Please let us know of there is

any damage.

5.2. Storage

Please keep the unit clean and dry area during storage.

If the pump is out of use for a long time, please consider the instructions

below.

1. If there is water inside the pump, drain it.

2. Clean the pump casing and impeller by jetting clean water for a short

time.

3. Empty water inside the pump casing, suction line and discharge line.

4. Add small amount of antifreeze inside the pump casing if it is not

possible to empty it completely. Rotate the pump shaft by hand to mix

the antifreeze.

5. Add liquid lubricator into the bearing and seal gap up

until the level

indicator.

6. Close the suction and discharge exits with gasket.

7. Spray an anti-corrosive into the pump casing.

8. Rotate the pump shaft by hand once in every month, in order to protect

it from freezing and to lubricate the bearings.

6. ASSEMBLY / INSTALLATION

6.1. Installation

In our standard production, the pump and the motor have been installed

in a common base plate.

6.1.1. Location of Installation

Pump will be installed in a location where the control and the

maintenance of the pump are easily made. The pump room should be

suitable for operation of lifting systems such as freight elevator, forklift,

etc.

6.1.2. Location of Installation- Local Ambient Temperature

When the local ambient room temperature exceeds +40

o

C in a pumping

system, suitable ventilation should be provided in order to remove the

heat dissipated to the environment and supply fresh air.

6.2. Type of Connection

Type of connection depends on the design type and the size of the pump

and the motor, as well as the local installation conditions. Foot-mounted

horizontal pump-motor units have been installed in a common base plate.

6.3. Foundation

6.3.1. General

In applications where a trailor is not used, the pump must be properly

fixed to solidified concrete base plate with studs.

Base plate of the pump must be grouted. The foundation shall be of

concrete or steel framework.

Note:

The foundation shall distribute the weight of the pumping group

evenly.

6.3.2. Main Properties of the Steel Framework Bases

Foundations with steel framework shall be designed in such a way that

the base plate is bolted or welded contacting to all area.

CAUTION

If base plate is supported from only four points, pump group will

stay in the middle, causing misalignment of the coupling and

increasing the noise level.

6.3.3. Foundation Properties

The foundation shall be horizontal, flat and clean and shall support all the

weight.

Note:

Reinforced concrete bases are constructed from standard concrete

with at least B 25 resistance class.

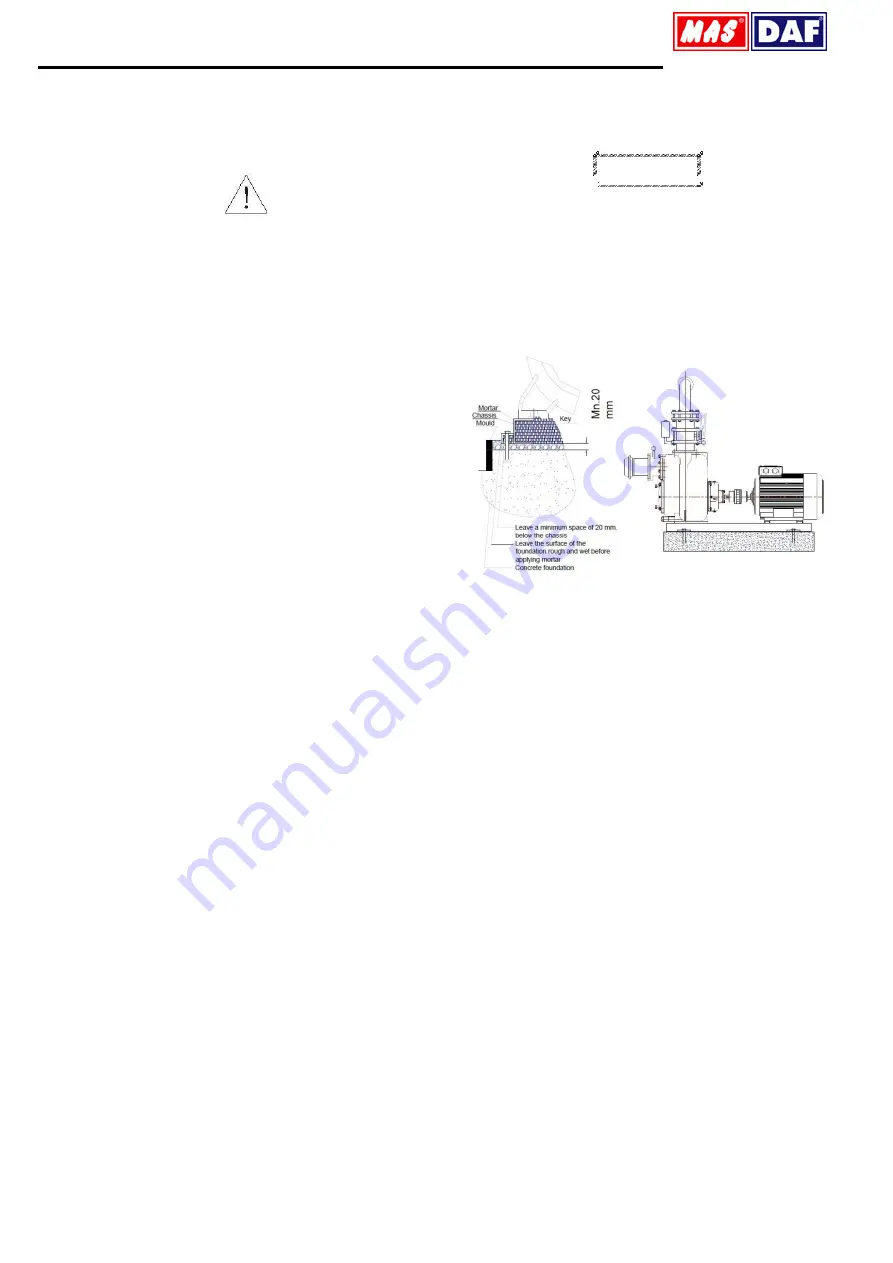

Figure 3:

Typical Concrete Foundations

6.4. Coupling Alignment

6.4.1. General

For a proper operation of a pump group, a good alignment of the coupling

is necessary. Vibration, noise, overheating of the bearings, overcharge

problems can be attributed to the misalignment of coupling or using an

improper coupling.

Flexible coupling does not correct the axial misalignments between

the pump and the motor axes. However, it allows pinpointing the

misalignments.

In order to avoid overheating, vibration, noise and wearing of the

rolling bearings, alignment of the coupling has to be made properly

and checked often.

Do not use a different coupling other than the original type installed

on pumping group.

6.4.2. Method of Coupling Alignment

When the motor moves towards the pump, a gap must be maintained in

order that the two faces of the coupling do not touch each other. The

recommended distance is 3 mm. To check the coupling alignment, a

conical measurement device and a gauge stick are needed.

1. Angular Misalignment (Figure 4)

In order to control the angular misalignment, the distance between the

two halves of the coupling is measured in both horizontal and vertical

planes. Measurements taken at four points shall be in agreement for the

alignment.

2. Parallel Axis Misalignment (Figure 4)

In order to control parallel axis misalignment, a smooth edged

gauge stick is pressed axially over the upper half of the coupling. Then,

the gauge stick is checked for the other half of the coupling. For

alignment, the gauge stick shall be in contact with both of the halves at

the same time. This procedure shall be repeated for four sides of the

coupling. (i.e. top, bottom, left and right sides of the coupling). When all

four sides give reasonably accepted results, alignment of the coupling

has been ensured.