11

Maintenance

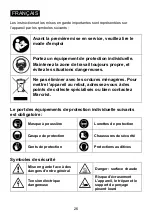

Make sure to disconnect the plug from the mains before beginning

maintenance or repair works.

Care of cutting tools and metal parts

Remove any dirt adhering to the surface of cutting tools, the chuck and drive

spindle and protect their surfaces from corrosion by rubbing them with an oil-

soaked cloth from time to time. Always keep the connection end clean and lightly

greased.

Care of the machine

CAUTION

Keep the machine, especially its grip surfaces, clean and free from oil and

grease. Do not use cleaning agents which contain silicone.

•

The outer casing of the machine is made from impact-resistant plastic.

•

Never operate the machine when the ventilation slots are blocked.

•

Clean the ventilation slots carefully using a dry brush.

•

Do not permit foreign objects to enter the interior of the machine.

•

Clean the outside of the machine at regular intervals with a slightly damp

cloth.

•

Do not use a spray, steam pressure cleaning equipment or running water for

cleaning. This may negatively affect the electrical safety of the machine.

Maintenance

WARNING

Repairs to the electrical section of the machine may be carried out only by trained

electrical specialists.

According to its design, the tool requires a minimum of care and maintenance.

However, the following maintenance works, and component checks have to be

performed at regular intervals:

•

Once per quarter of a year, an electrical specialist should check the switch,

cable and plug.

Replacing the carbon brushes

DANGER

Failure to observe the following instructions may result in contact with dangerous

electric voltage.

•

Disconnect the machine from the electric supply.

Содержание DDM150

Страница 1: ...1 ...