Part Number 020002365 08/25/2015 29

Section 2

Installation

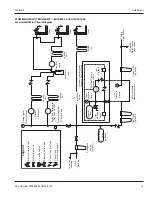

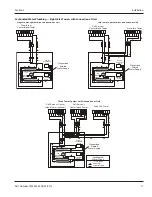

CONNECTING THE PRE-CHARGED REFRIGERATION

LINES

Important

When the connections are made, the seal in the

couplings are broken and if removed for any reason, the

refrigerant charge will be lost.

NOTE: Before connecting the pre-charged refrigeration

lines, the refrigeration unit must be properly located,

leveled, and the water bath filled 1" (2.5 cm) below the

installed drain pipe.

1. Attach low side gauge set to service port on each line

set to verify positive pressure within the line set.

NOTE: If for any reason the lines are damaged and/or

leaking, the lines are no longer charged or if the line set is

too long for the application, refer to “Installing the Multiplex

Remote Condenser”.

2. Always make the connections at the condenser first,

using the end of the pre-charged lines with the valve

ports.

3. Connect the condenser side with the quick connectors

(discharge and liquid) up to condenser. Refer to

the section titled “Aeroquip Connection” in these

instructions.

4. Connect the refrigeration unit side with the quick

connects (discharge and liquid). Make sure to provide

a discharge trap at back of refrigeration unit, or bend

discharge line down 12" and then up smoothly (no

kinks) to provide a trap.

5. If a low refrigerant charge is detected, recover and

recharge the system adding the unit name plate

charge.

6. Repair any damages to the line sets before proceeding.

Testing

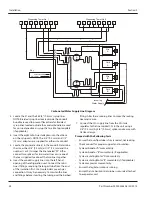

TESTING CO

2

CIRCUIT FOR LEAKS

It is advisable to test the system for leaks before turning

ON

the water supply to the carbonator and connecting the

syrup tanks. If a leak does exist, it will be easier and faster to

make any correction.

1. Turn ON the CO

2

supply and adjust the primary

regulator to 90 psi (6.2 bar)(620528.156099999906

Pascals).

2. Position the CO

2

tank changeover valve handle (if

applicable) toward this regulator.

3. Move the air/CO

2

changeover valve to the CO

2

position

(if applicable).

4. Allow the CO

2

gas to enter the system.

5. Wait for 2 or 3 minutes before turning OFF the CO

2

tank

valve. This will allow the lines to expand under pressure.

6. Turn OFF the CO

2

tank valve. Observe the pressure

on the high pressure gauge (not the 90 psi [6.2 bar]

[620528.156099999906 Pascals] operating gauge).

The needle may drop approximately 1 psi (.09 bar)

(6894.75729 Pascals), but must remain constant and

not lose pressure. Wait for several minutes.

If pressure continues to fall, this indicates there is a leak in

the system which must be corrected.

The greater the leak, the faster the pressure will drop. The

smaller the leak, the slower the gauge will drop.

It may be necessary to use a soap solution at all

connections to locate a very small leak.

CO

2

gas must be present on all valves of the tower(s)

NOTE: All soap solution must be rinsed thoroughly from

tubing upon completion of testing.

TESTING SYRUP CIRCUIT (5 GALLON TANKS ONLY)

Before connecting the syrup tanks to the system, the syrup

circuits must be tested for leaks with CO

2

gas.

1. Connect an empty syrup tank to pre-mix syrup circuits.

2. Connect one of the CO

2

gas quick disconnects to this

tank. Allow the tank to fill with CO

2

gas.

3. Observe the pressure of the primary CO

2

tank regulator

(not the 90 psi [6.2 bar][620528.156099999906

Pascals]).

4. Allow the CO

2

tank pressure to remain ON for a few

seconds. This will allow the lines to expand to operating

conditions.

5. Turn OFF the CO

2

tank cylinder.

6. Check all connections from the syrup tank through the

connections in the water bath area to all fittings at rear

of tower.

7. Check syrup circuitry on the tower by activating the

valve.

8. Follow the same procedure for the diet pre-mix

beverage circuit.

If no leaks are found in the syrup circuits and the

carbonated water circuit, the system is ready to be insulated

and placed in operation.

Содержание Multiplex 42 MR04

Страница 8: ...8 Part Number 020002365 08 25 2015 General Information Section 1 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 44: ...44 Part Number 020002365 08 25 2015 Maintenance Section 4 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...50 Part Number 020002365 08 25 2015 Troubleshooting Section 5 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 51: ...Part Number 020002365 08 25 2015 51 Section 5 Troubleshooting THIS PAGE INTENTIONALLY LEFT BLANK ...