7

TPM 092/13

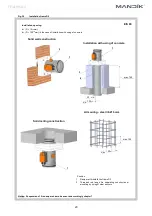

Fig. 11 Communication and Supply Device

BKN 230-24

Tab. 2.3.1. Communication and Supply Device BKN 230-24

2

Communication and Supply Device

BKN 230-24

Nominal voltage

AC 230V 50/60Hz

Power consumption

3,5 W (operating position)

Dimensioning

11 VA (including actuating mechanism)

Protection Class

II

Degree of protection

IP 42

Ambient Temperature

Storage Temperature

- 30 °C

+ 50 °C

- 40 °C

+ 50 °C

Connection - mains

- drive

- terminal board

Cable 0,9 m with EURO plug of 26 type

6 pole plug, 3 pole plug

screw terminals for conductor 2x1,5 mm

3.1.

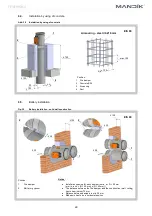

BKS 24-9A communication and control device is used for group control and checks of 1 to 9 fire

dampers with the actuating mechanism BLF 24-T-ST in connection with the supply and

communication device BKN 230-24. Signalisation of the damper position is individual; the

dampers can be controlled and tested only as a group. BKS 24-9A is intended for use in the

distribution board and displays the operation situations and failure reports of the connected fire

dampers. It is possible to signalise functions such as the damper position and failure reports or to

transmit them further to the system by means of integrated auxiliary switches. BKS 24-9A

receives signals from BKN 230-24 through the two-conductor wiring and issues control

commands. Proper damper operation is indicated by two light LED diodes:

Control ON = position OPERATION

Control OFF = position FAILURE

If the fire dampers do not reach the given position in time tolerable for displacing, the appropriate

light diode FAILURE starts to flash and K1 contact is opened (current failure). In case that the

faulty damper finally reaches its given position, K1 is closed and the failure report light shines (the

failure is saved in memory).

K2 - the auxiliary contact - is used for signalisation of the flap position to the master device. Function

of this auxiliary contact can be programmed through the terminal 14 according to the Tab. 3.1.1.

3. Communication and control devices