25

TPM 083/12

15.2.

Manual operation

Without power supply, the damper can be operated manually and fixed in any required position.

Release of the locking mechanism can be achieved manually or automatically by applying the

supply voltage.

15.3.

It is recommended to provide periodical checks, maintenance and service actions on Fire

Equipment by Authorized persons schooled by Producer.

15.4.

All effective safety standards and directives must be observed during fire damper assembly.

Check of blade displacement into the breakdown position "CLOSED" can be done after cutting

off the actuating mechanism supply (e.g. by pressing the RESET button at the thermoelectrical

starting mechanism BAE 72B-S or cutting off the supply from ELECTRICAL FIRE

SIGNALISATION). Check of blade displacement back into the "OPEN" position can be done after

restoration of power supply (e.g. By releasing the RESET button or restoration of supply from

ELECTRICAL FIRE SIGNALISATION).

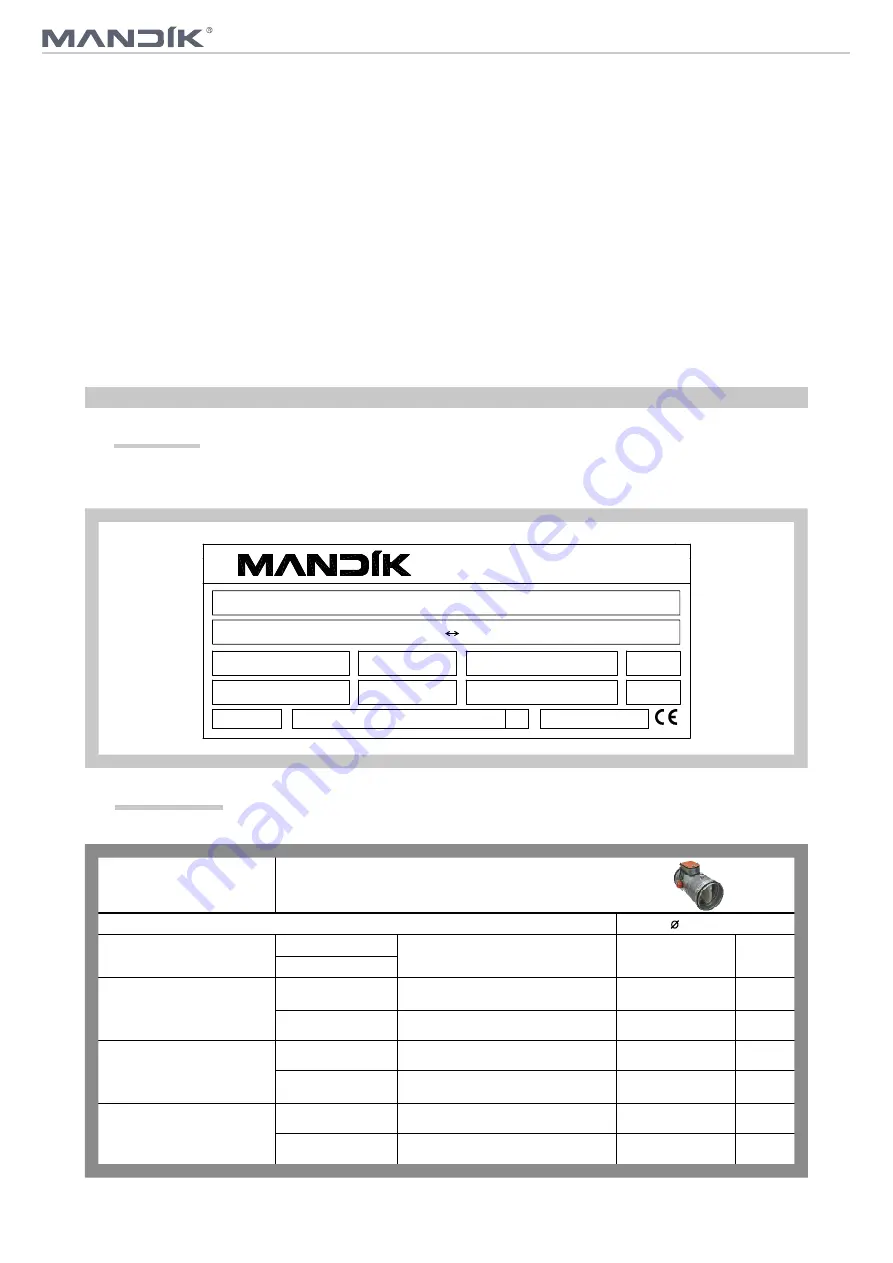

VIII. DATA OF THE PRODUCT

16. Data label

16.1.

Data label is placed on the casing of fire damper.

Fig. 27 Data label

Certificate:

WEIGHT (kg):

Dob

ř

íšská 550

267 24 Hostomice

MANDÍK, a.s.

Czech Republic

FIRE DAMPER FDMC

DESIGN:

SERIAL NUMBER:

SIZE:

1391

1391-CPR-0090/2014

14

EN 15650:2010

CLASSIFICATION:

EI 60 (ve ho i o) S

TPM083/12

17. Quick review

Damper

FDMC

Size

100 - 400

Fire separating construction

Wall/Ceiling

Installation

Fire resistance

Fig.

Min. thickness [mm]

Solid wall construction

100

Mortar or gypsum

EIS 60

16

100

Stuffing box with fire protection mastic

EIS 60

17

Gypsum wall construction

100

Mortar or gypsum

EIS 60

18

100

Stuffing box with fire protection mastic

EIS 60

19

Solid ceiling construction

150

Mortar or gypsum

EIS 60

20

150

Stuffing box with fire protection mastic

EIS 60

21

Tab. 17.1.1. Quick review

Содержание FDMC

Страница 1: ......