Water supply

Never

operate

the

heat

pump

without

water

flowing

through

its

water-to-refrigerant

heat

exchanger

coil.

This

may

cause

severe

damage

to

the

unit.

For

proper

water

flow

rates,

refer

to

the

unit

catalog.

Condensate

Condensate

Condensate

Condensate

Drain

Drain

Drain

Drain

See

Figures

7

and

8

The

condensate

drain

is

set

up

for

a

7/8-inch

OD

copper

connection.

The

condensate

pipe

or

hose

installed

must

have

a

minimum

1-inch

trap

in

the

condensate

line.

All

condensate

piping

must

pitch

away

from

the

unit

for

proper

drainage.

Check

local

codes

for

compliance.

Note:

Note:

Note:

Note:

All

vertical

units

have

an

internal

1-inch

trap

built

into

the

condensate

line.

All

units

require

a

field-installed

condensate

line.

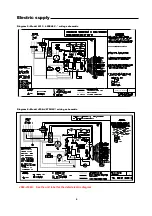

Figure

7:

Condensate

trap

detail

–

vertical

unit

5.

After

it’s

been

completely

cleaned

and

drained,

fill

loop

with

water

at

an

alkaline

level

of

approximately

pH

7.5.

6. Connect

heat

pump

to

the

piping

loop.

7.

Make

sure

all

entrained

air

is

purged

from

loop

and

each

unit

is

operating

at

its

specified

flow

rate.

Figure 8: Condensate trap

detail

–

horizontal

unit

Drain Pan

1" Min. Internal Trap

(By Mammoth)

Closed

Closed

Closed

Closed----Loop

Loop

Loop

Loop

Systems

Systems

Systems

Systems

Follow

these

steps

to

install

closed-loop

systems.

1.

Leave

unit

unconnected

or

isolated

using

shutoff

valves

as

building

water

loop

is

initially

flushed.

2.

Fill

water

system

with

1

lb.

trisodium

phosphate

for

every

50

gallons

of

water.

3.

Purge

piping

of

trapped

air;

set

supplemental

heater

to

maintain

110

F;

and,

circulate

solution

for

approximately

8

hours.

4.

Drain

system

completely

and

repeat

the

entire

flushing

process,

if

necessary

Optional

Optional

Optional

Optional

Hose

Hose

Hose

Hose

Kits

Kits

Kits

Kits

W

W

W

Water

ater

ater

ater

Hoses:

Hoses:

Hoses:

Hoses:

300mm

and

600mm

flexible

water

hoses

are

available

for

connections

to

the

heat

pump

and

adapters.

Use

two

properly

sized

wrenches,

one

on

the

unit

FPT

fitting

and

one

on

the

hexagonal

fitting

when

connecting

hoses.

Do

not

use

wrench

on

hose

or

on

the

sleeve

that

crimps

the

fitting

onto

the

hose.

Hoses

must

not

be

pulled

taut,

twisted

or

kinked.

Connections

should

not

be

over

tightened.

Before

pressurizing

the

water

system,

closely

inspect

hoses

and

fittings

to

be

sure

there

are

no

cuts,

abrasions,

twists,

or

kinks.

Make

sure

hoses

will

not

be

in

contact

with

any

sharp

surface

or

edge

while

in

use.

4

7/8" O.D.

Condensate

1" Min. Internal

Trap (By Others)