9

1

10

2

11

3

12

4

13

5

14

6

15

7

16

8

11

Microprocessor

control

For

a

complete

description

of

the

operation

of

the

Microprocessor

Control,

see

Operating

Manual

D-5.

Basic

Basic

Basic

Basic

Features

Features

Features

Features

Fan

Fan

Fan

Fan

Speed

Speed

Speed

Speed

Control:

Control:

Control:

Control:

Adjusts

fan

speed

100-80

percent

on

single-circuit

direct-drive

units.

Diagnostic

Diagnostic

Diagnostic

Diagnostic

LEDs:

LEDs:

LEDs:

LEDs:

Red

=

Fault

in

safety

circuit.

Yellow

=

Compressor

on

(not

blinking).

Green

=

Power

on

(24

VAC

is

present

at

board).

Random

Random

Random

Random

Start:

Start:

Start:

Start:

Prevents

power

surges

by

delaying

unit

startup

by

5-35

seconds

so

that

all

units

do

not

start

at

the

same

time.

Occurs

only

when

unit

comes

off

of

either

shutdown,

unoccupied

or

high/low

voltage

modes.

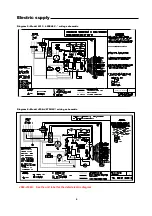

TERMINAL

SIRIP

7

8

13

14

1

12

11

3

10

15

16

5

6

4

9

2

24 VAC (–)

24 VAC

(+) FAN

COMPRESSOR

LOCKOUT ALARM

REVERSING VALVE

A.D. CONTACT (N.O.)

A.D. CONTACT (COM)

※

SEE

※

NOTE

UNOCCUPIED INPUT

NSB / U SIGNAL

EMERGENCY SHUTDOWN

2-HOUR OVERRIDE

DRY CONTACT

ALARM OUTPUT

C

R

G

Y

L

O

Sy

Sc

2

1

4

3

6

5

8

7

MICROPROCESSOR CCG

SEE NOTE 5 CC

ALARM

Testing

Procedure

Procedure

Procedure

Procedure

The

microprocessor

control

board

should

be

tested

while

installed

in

a

unit

with

a

thermostat

attached.

Caution:

Caution:

Caution:

Caution:

When

removing

or

jumping

wires,

be

extremely

careful

not

to

short

the

secondary

side

or

come

in

contact

with

line

voltage.

The

following

procedure

outlines

how

to

test

the

microprocessor

control

board’s

individual

functions

while

installed

in

a

unit.

1.

Move

shunt

#1

to

“test”

position.

2.

Apply

voltage

to

the

unit

assuring

the

microprocessor

control

board

is

accessible

for

troubleshooting.

3.

Take

meter

readings

as

indicated

below.

Fan

Fan

Fan

Fan

Function:

Function:

Function:

Function:

On

a

call

for

fan

operation

.

.

.

“C”

to

“G”

terminals

should

read

24

volts.

“L1”

to

“L2”

line

voltage

should

match

incoming

line

voltage

(208,

220,

230,

265,

380

or

460

volts).

F

FF

Fan

an

an

an

Speed

Speed

Speed

Speed

Control:

Control:

Control:

Control:

On

a

call

for

fan

function

.

.

“FAN”

to

“FAN

COM”

measured

voltage

should

vary

with

adjustment

of

speed

controller

stem.

Compressor:

Compressor:

Compressor:

Compressor:

On

a

call

for

compressor

function

.

.

.

“C”

to

“Y”

terminals

should

read

24

volts.

Contact

terminals

“SY”

to

“SC”

should

read

0

ohms.

Terminals

“SC”

to

#2

should

now

be

open.

Overflow

Overflow

Overflow

Overflow

Detector:

Detector:

Detector:

Detector:

Jumper

from

“SENSOR”

terminal

to

ground

unit

should

lock

out

unit.

“L”

to

“R”

terminals

should

read

24

volts

if

“COM

/

24

VAC”

shunt

is

set

to

“COM”.

Lockout:

Lockout:

Lockout:

Lockout:

Pull

either

wire

HPI,

LPI

or

AUX1

while

unit

is

running.

Unit

should

lock

out.

“L”

to

“R”

terminals

should

read

24

volts

if

“COM

/

24

VAC”

shunt

is

set

to

“COM”.

Return

shunt

#1

to

“RS”

(random

start)

or

“NO

RS”

depending

on

application.

Remove

any

additional

jumpers

and

return

all

wiring

back

to

its

original

configuration.

Condensate

Condensate

Condensate

Condensate

Overflow:

Overflow:

Overflow:

Overflow:

A

sensor

in

the

drain

pan

electrically

senses

the

presence

of

water. Switch

is

tied

to

the

safety

lockout

circuit.

Compressor

Compressor

Compressor

Compressor

Anti

Anti

Anti

Anti----short

short

short

short

Cycle:

Cycle:

Cycle:

Cycle:

A

5-minute

time

delay

prevents

compressor

short

cycling

and

extends

motor

life.

Optional

Optional

Optional

Optional

Field

Field

Field

Field

Adjustments

Adjustments

Adjustments

Adjustments

No

No

No

No

Random

Random

Random

Random

Start:

Start:

Start:

Start:

A

jumper

allows

elimination

of

the

random

start

feature.

TTTTest

est

est

est

Mode:

Mode:

Mode:

Mode:

A

jumper

allows

elimination

of

all

time

delays

to

simplify

unit

checkout

operation

by

qualified

service

personnel

only.

Auto

Auto

Auto

Auto----Reset:

Reset:

Reset:

Reset:

A

jumper

allows

auto-reset

of

the

safety

trip.

The

unit

will

automatically

reset

after

20

minutes.

Fault

Fault

Fault

Fault

Output:

Output:

Output:

Output:

A

terminal

allows

connection

of

an

auto-

changeover

thermostat

with

an

LED.

Signal

may

be

24

VAC

(+)

or

(–).

LED STATUS:

Yellow “On” . . . . . . . . . . . Compressor On

Green “Off” . . . . . . . . . . . No 24 VAC

Green “On” . . . . . . . . . . . 24 VAC Present

Green “1 Flash” . . . . . . . . . Low Voltage

Green “2 Flash” . . . . . . . . . High Voltage

Red “Off” . . . . . . . . . . . . . . No Faults (Normal)

Red “On” . . . . . . . . . . . . . . Emergency Shutdown

Red “1 Flash” . . . . . . . . . . . H.P. Fault

Red “2” Flash” . . . . . . . . . . L.P. Fault

Red “3 Flash” . . . . . . . . . . . W.T. Fault