Instruction Manual

MAN-004

16

www.macmedical.com

Instructions for Cleaning Stainless Steel Surgical Scrub Sinks

Stainless steel sinks must be cleaned on a regular basis to prevent any unnecessary damage to the stainless

steel surfaces.

When cleaning Ssainless steel sinks, make sure to use the proper approved cleaning agents and cleaning

materials.

CAUTION

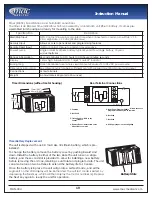

DO NOT USE

these Cleaning Materials

CAUTION

DO NOT USE

these Cleaning Agents

Abrasive Pads

Hard Water (water with a pH reading above 7.0).

Scrapers

Hydrochloric Acid

Steel Wool

Steam or high pressure water

Wire Brushes

Bleach or any compounds containing chlorine or Soldium

hypochlorate, or ammonium chloride salts.

Approved cleaning materials and agents

•

Soft, clean lint-free cloth

•

Non-abrasive cleaning pads

•

Soft bristle brush

•

Mild detergents

• Sodium Bicarbonate (baking soda)

• Distilled water (pH rating 7) alone or with a mild detergent

•

White vinegar (in a spray bottle)

•

Isopropyl Alcohol

• Hospital-grade non-bleach disinfectants

•

Cleaners approved for use on stainless steel

Cleaning Stainless Steel Surfaces

1. Using a damp, lint-free cloth and approved cleaner, wipe down the entire exterior surface of the stainless

steel sinks. Using a damp, lint-free cloth with distilled water and a mild detergent, wipe down the entire

exterior surface of the stainless steel sinks.

2. Let cleaned sinks air dry.

Cleaning Decals or Printed Labels

•

Use only distilled water and a mild detergent applied with a clean, dry lint-free cloth to clean decals or

printed labels.

•

Cleaning agents can remove or smear any printing from decals and print labels.

•

Cleaning agents can damage plastic materials used in manufacturing covers for electronic items such as

infrared sensor face.