M3LU

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: [email protected]

EM-2652-A Rev.2 P. 6 / 9

■

OUTPUT TYPE (SW2 & 1)

Table 10

OUTPUT

SW2-8

SW2-7

SW1-4

SW1-3

SW1-2

SW1-1

0 – 20 mA

OFF

OFF

OFF

ON

OFF

OFF

-2.5 – +2.5 V

OFF

ON

ON

OFF

OFF

ON

-10 – +10 V

ON

OFF

ON

OFF

ON

OFF

■

OUTPUT TYPE / PC CONFIG (SW1)

Table 11

OUTPUT

SW1-4

SW1-3

SW1-2

SW1-1

0 – 20 mA

OFF

ON

OFF

OFF

-2.5 – +2.5 V

ON

OFF

OFF

ON

-10 – +10 V

ON

OFF

ON

OFF

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) DIP SW setting: Check that the switches are set to ap-

propriate positions.

3) Power input voltage: Check voltage across the terminal

10 – 12 (AC) or 11 – 12 (DC) with a multimeter.

4) Input: Check that the input signal is within 0 – 100% of

full-scale.

If the thermocouple, RTD, potentiometer, resistance or

their extension wires are broken, the output goes over

100% (below 0% with downscale protection) due to burn-

out function. Confirm the status indicator LED pattern

and check leadwires in such a case.

5) Output: Check that the load resistance meets the de-

scribed specifications.

I/O RANGING & FINE ADJUSTMENTS

After the DIP SW setting is complete, set up the precise

input and output range using the front control buttons. Be

sure that the front control button function is enabled with

the DIP switch setting.

The front LEDs’ colors and blinking patterns help you to

easily identify the transmitter’s status and confirm the set-

up actions in each step of Calibration Modes. Please read

the following explanations referring to “Calibration Flow

Chart”.

■

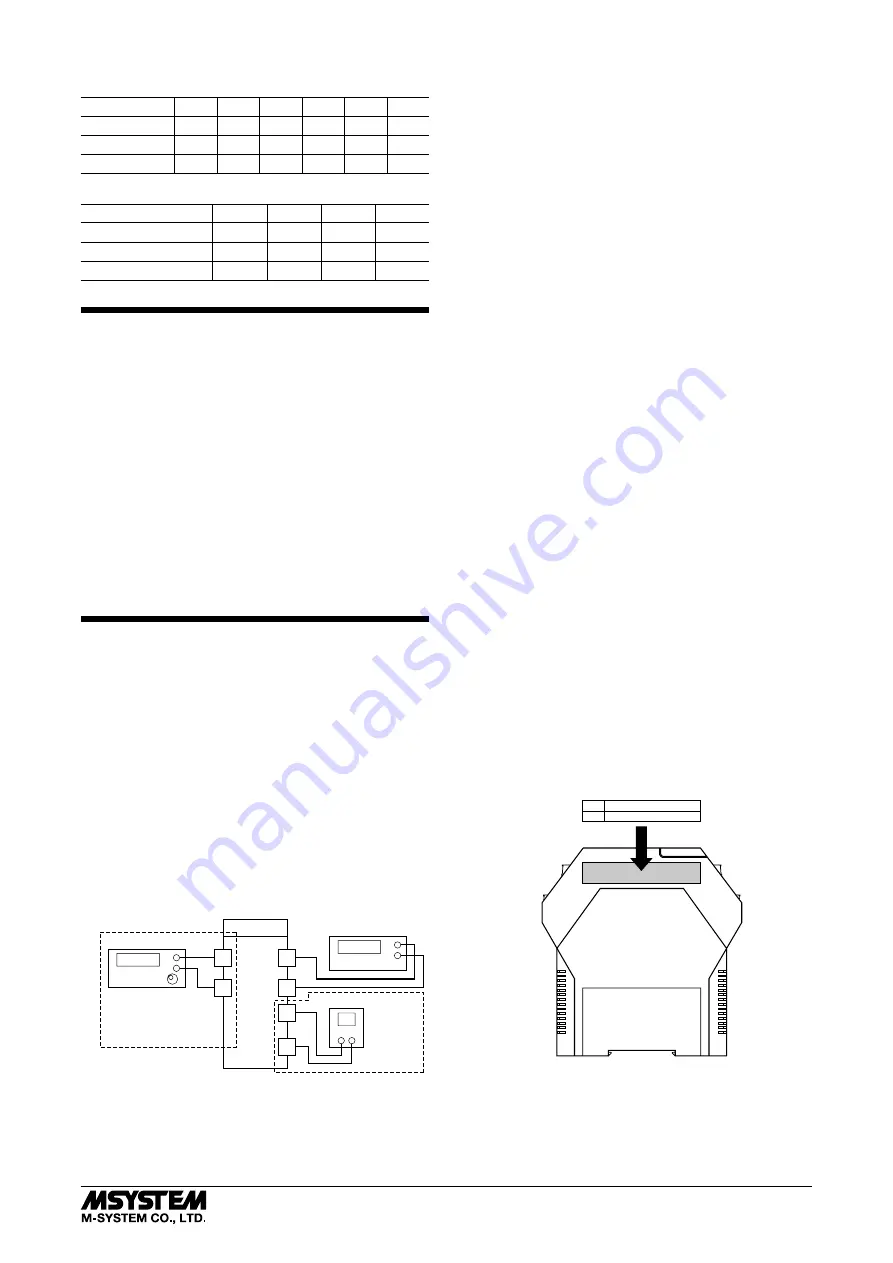

PREPARATION (e.g. M3LU-R4/A, DC powered type)

1) Mount the DIP-SW-configured M3LU on to a DIN rail.

2) Connect the M3LU to a simulator and a multimeter and

to a DC power source as shown below.

3) Turn the power supply on and wait for 10 minutes.

3

5

7

8

11

12

M3LU

Multimeter

Simulator

+

–

Power Source

+ –

+

–

Example with V/mA input.

See Connection Diagram

for other input types.

Example with

DC power.

■

INPUT & OUTPUT RANGING

[Example] Setting both input and output to 1 – 5 V DC

1) Run Mode: Confirm that the green LED is blinking (mod-

el M3LU-x/A) or the green LED turns on (model M3LU-

x/B).

2) Input Ranging Mode: Hold down MODE button for longer

than 5 seconds until the LD1 red LED is ON and the LD2

red LED is blinking.

3) 0% Input Ranging: Apply the desired minimum input

level (e.g. 1 V) from the simulator and hold down DOWN

button until the LD1 blinks for approx. 2 sec. and then

turns OFF. When you release the button, the LD1 is re-

turned to ON.

The blinking LD1 means that the value is stored in the

memory. If the LED does not change, the entered level

may be inappropriate: too small a span, or out of usable

range (same for all steps).

4) 100% Input Ranging: Apply the desired maximum input

level (e.g. 5 V) from the simulator and hold down UP but-

ton until the LD1 blinks for approx. 2 sec. and then turns

OFF. When you release the button, the LD1 is returned

to ON.

5) Output Ranging Mode: Press MODE button and confirm

that the LD3 red LED instead of LD2 is blinking.

6) 0% Output Ranging: Increase or decrease the simulated

input until the meter shows the desired minimum output

level (e.g. 1 V). Hold down DOWN button until the LD1

blinks for approx. 2 sec. and then turns OFF. When you

release the button, the LD1 is returned to ON.

7) 100% Output Ranging: Increase or decrease the simu-

lated input until the meter shows the desired maximum

output level (e.g. 5 V). Hold down UP button until the

LD1 blinks for approx. 2 sec. and then turns OFF. When

you release the button, the LD1 is returned to ON.

8) Run Mode: When calibration is completed, press MODE

button once and confirm that: the LD1 green LED is

blinking in case of M3LU-x/A; and the LD1 green LED is

ON in case of M3LU-x/B.

■

I/O RANGE LABEL

Blank I/O range labels are included in the product package.

Write in the configured ranges and put the label on the side

as shown below.

INPUT

OUTPUT

I/O Range Label (included in the product package)