REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

DATE

10.06.99

ENDORSED

COMPILER TECO/ATI

40

DISASSEMBLY/REASSEMBLY

VIII

89

90

91

92

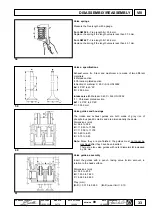

Cylinders

Reset the comparator with a calibrated ring.

Check diameter D in points 1, 2 and 3; repeat the same operation by

turning the comparator through 90° at the same levels.

Check for possible wear in zone X where the piston rings operate and

grind the cylinder to the next allowance if it exceeds the max. given

limit (e.g. 72 mm) by 0.05 mm.

Dimensions (mm) LGW 523, LGW 627 = 71.990 to 72.000

The diametrical values given belong to class A cylinders to which

pistons of the same class must be coupled, see fig. 71.

To check the coupling play with the pistons, measure the diameter of

zone Z of each cylinder according to the axis perpendicular to the

crank shaft.

Cylinders, class

The class references of the pistons (A, B, C,) are on the piston

crowns while those of the cylinders are on the cylinder block, in the

places indicated by the arrows (see fig. 91).

Note: For engine LGW 523 with aluminium cylinder block, the cast

iron cylinders can be normally ground to 0.5 and 1.0 mm

allowances.

The cylinders must not be replaced.

It is forbidden to touch up the inner surfaces of the cylinders

with emery paper.

Cylinders, roughness

The slant of the crossed honing marks must be between 45° and 55°.

These marks must be clear and uniform in both directions.

The average roughness must be between 0.5 and 1 µ (micron).

The entire surface of the cylinder that comes into contact with the

piston rings must be machined by the faceplate method.

FLYWHEEL

SIDE

TIMING

SYSTEM

SIDE