REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

DATE

10.06.99

ENDORSED

COMPILER TECO/ATI

28

37

39

38

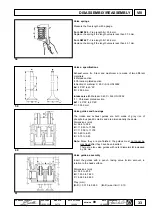

LGW 627 rocker cap

Many of the more important engine components are on the cylinder

head.

The rocker cover houses part of the camshaft lubrication duct, that

of the rockers and part of the engine bleeding system.

External parts of the rocker cover:

1 Screw to fix the rocker cover to the cylinder head

2 Pressure switch (the only point where the engine oil pressure can

be gauged)

3 Oil fill plug

Tighten the fixing bolts to a 9 Nm torque when remounting the cover.

Rocker cover and recirculated oil vapour bleeding system for

engine LGW 627

Internal parts of the rocker cover:

1 Camshaft and rocker rod lubrication ducts

2 Oil vapour cooling labyrinth

3 Vent vacuum valve

4 Space allowing oil vapour to pass from the cylinder head to the

rocker cover

5 Outlet for vapour re-converted into oil by cooling in the labyrinth

with consequent return to the sump

6 Outlet to vent oil vapours from the duct to the intake manifold

7 Hole to drain oil from the cylinder head

8 Oil return from bleed to sump (see description in point 5)

9 Seal between rocker cover and cylinder head

The rocker cover seal ensures that the rocker pivot camshaft

lubrication circuit is tight. It is therefore advisable to replace it

whenever it is demounted and to remount it with particular care.

Damage or breakage of the seal could lead to a pressure drop in the

lubrication circuit.

Torque the fixing screws to 9 Nm when remounting the cover.

By physical principle, oil vapours reach the cylinder head from the

top part of the engine through hole 4 fig. 38.

The moment in which the vapours approach the cover inlet, they are

attracted by the vacuum created in the intake manifold (with the aid

of valve 3 of fig. 38) with which the cover is in communication (from

6 to intake manifold see fig. 39 ).

To prevent excessive amounts of oil from reaching the manifold

along with the vapour in certain extreme conditions (e.g. lack of filter

maintenance, wear on the cylinders, etc.), the venting system has

been designed to decant the drops of oil during its passage through

labyrinth 2 of fig. 38 and to allow them to return to the sump along

the route (5 --> 8 of fig. 39).

Vapour that is not re-converted into oil enters intake manifold 6 of

fig. 39.

DISASSEMBLY/REASSEMBLY

VIII